D79 Series

D7 Series

S7 Series

B7 Series

K7 Series

E7 Series

C7 Series

A7 Series

L7 Series

DM01 Mid Drive Motor

Torque Sensor /

Cadence Sensor

With up to 1000W power, 160Nm torque, and an integrated sensor, it offers superior performance. It’s also IP65 waterproof for all-weather suitability

The key Features of

DM01 Mid Drive E-bike

Motor!

1000w

160NM

160RPM

48V/52V/60V

-20C~50C

IMPORTANT: To ensure optimal performance and avoid potential damage, please select the DM mid-drive motor with the same voltage rating as your chosen battery.

If you intend to use a different voltage battery later, kindly consult the factor for compatibility confirmation before making the switch.

Please note that motor damage caused by the unauthorized use of non-compatible batteries will not be covered under the after-sales warranty

- Description

- Parameter

- Specification

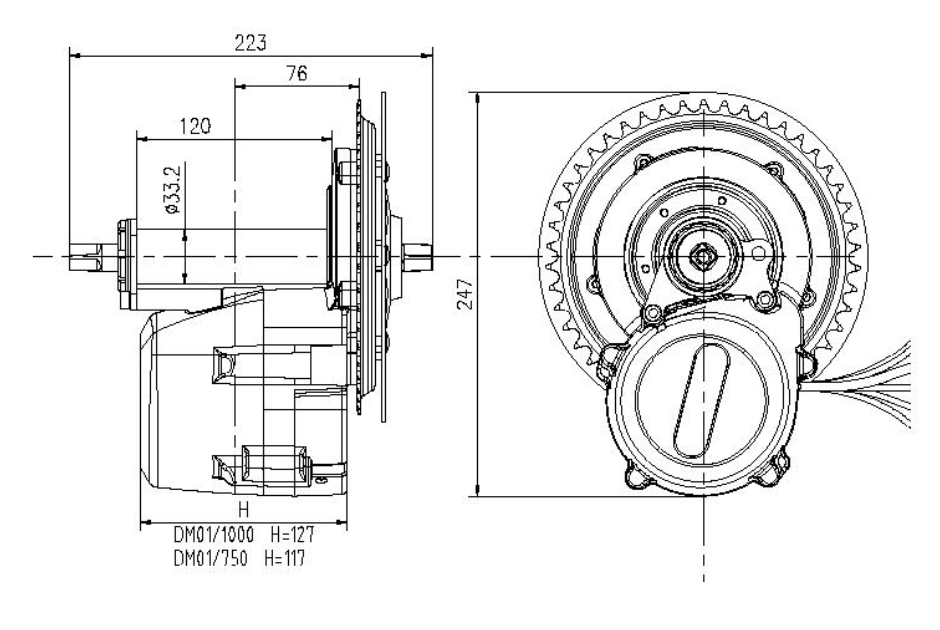

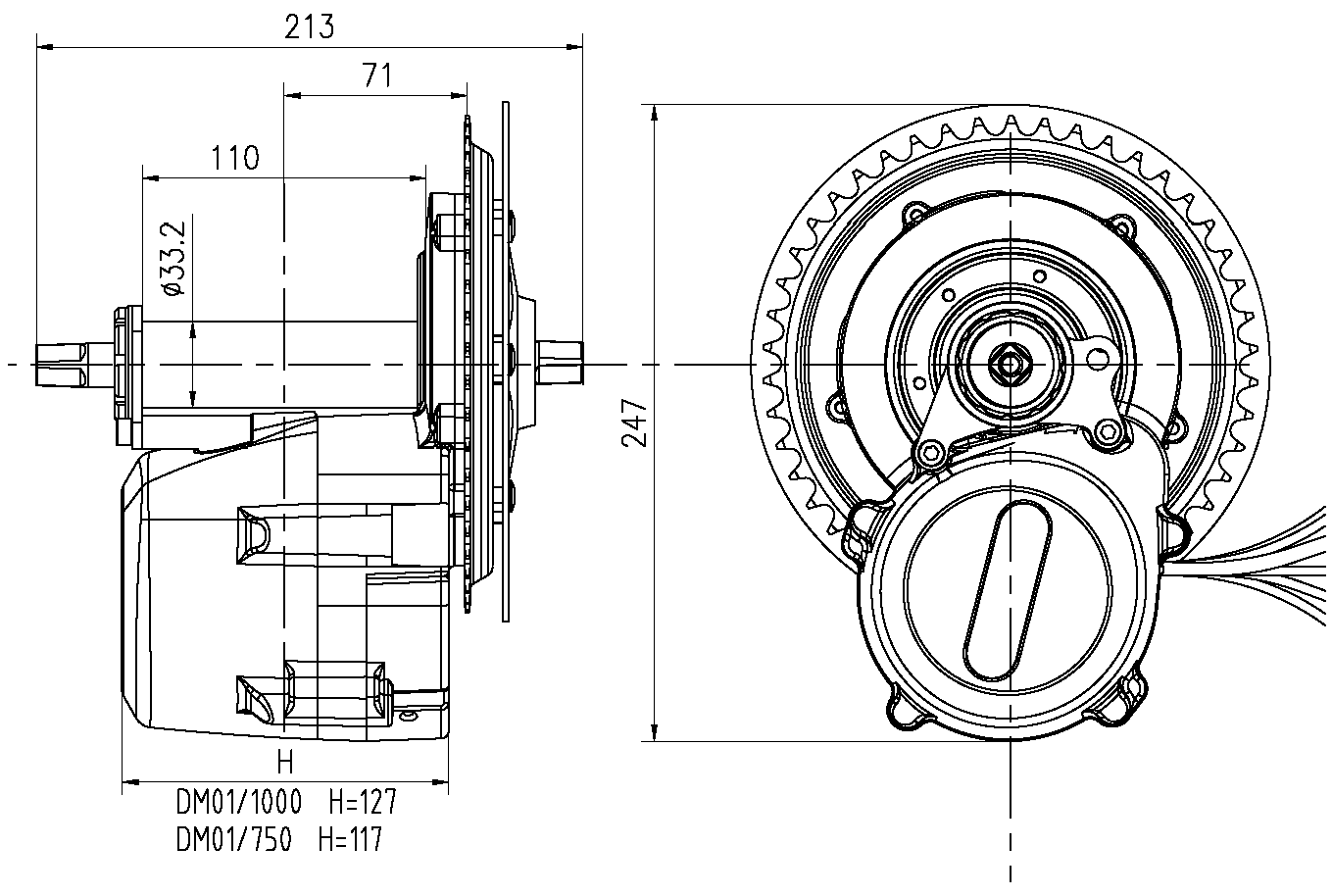

- Dimensions

- Diagram

- Installation

TRANSFORM YOUR ORDINARY BIKE WITH OUR DM01 E-BIKE MID-DRIVE MOTOR!

POWER AND COMPATIBILITY

DM01 E-bike Mid-Drive Motor:

Equipped with Torque Sensor & Cadence Sensor.

Up to 1000W Rated Power Output.

Output Torque of 160Nm.

Compatible With 48, 52, 60 Volts Battery Range.

Enhanced Performance

Better heat dissipation ensures cooler and longer operation, optimizing E-bike motor efficiency.

Enhanced power output ranging from 750W to 1000W for dynamic e-bike performance.

High gear ratio (40.27) provides swift starts and impressive climbs.

Dual-clutch mechanism offers minimal resistance when pedaling E-bike mid-drive motors.

INTEGRATION AND DESIGN

Seamless integration with 95% of standard bike frames for easy installation of E-bike mid-drive motors.

Engineered for a smooth, comfortable journey, resembling the traditional bicycle feel.

Crafted from robust Aluminum alloys, ensuring durability in various environments.

Trusted by top electric bicycle manufacturers for enduring performance.

Elevate Your E-bike Journey Today !

Attention: To ensure optimal functioning and longevity, we highly recommend using the motor within the prescribed voltage range. Any unauthorized alterations beyond this range may void the warranty coverage.

ADDITIONAL INFORMATIONS

| Mounting Position | Central |

|---|---|

| Shell Color | Black/Silver |

| Rated Power | 750W/1000W |

| Rated Voltage | 48V/52V |

| Reduction Gear Ratio | 40.27:1 |

| Max.Speed | 160rpm |

| Max Torque | 160N.m |

| Sensor Style | Cadence/ Torque sensor |

| Teeth Species | 46T(or 34T/36T/ 38T/42T/52T) |

| BB Axle | ~68mm~73mm ~100mm~110mm ~100mm~120mm |

| Noise Level | <50dB |

| Work Temperature | -20℃ ~ 50℃ |

| Motor Weight | 5.8kg/6Kg |

| Waterproof Level | IP65 |

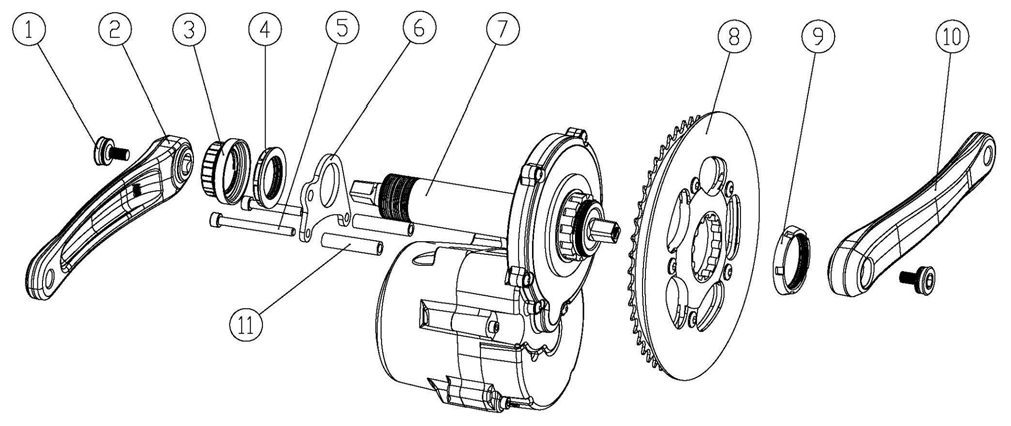

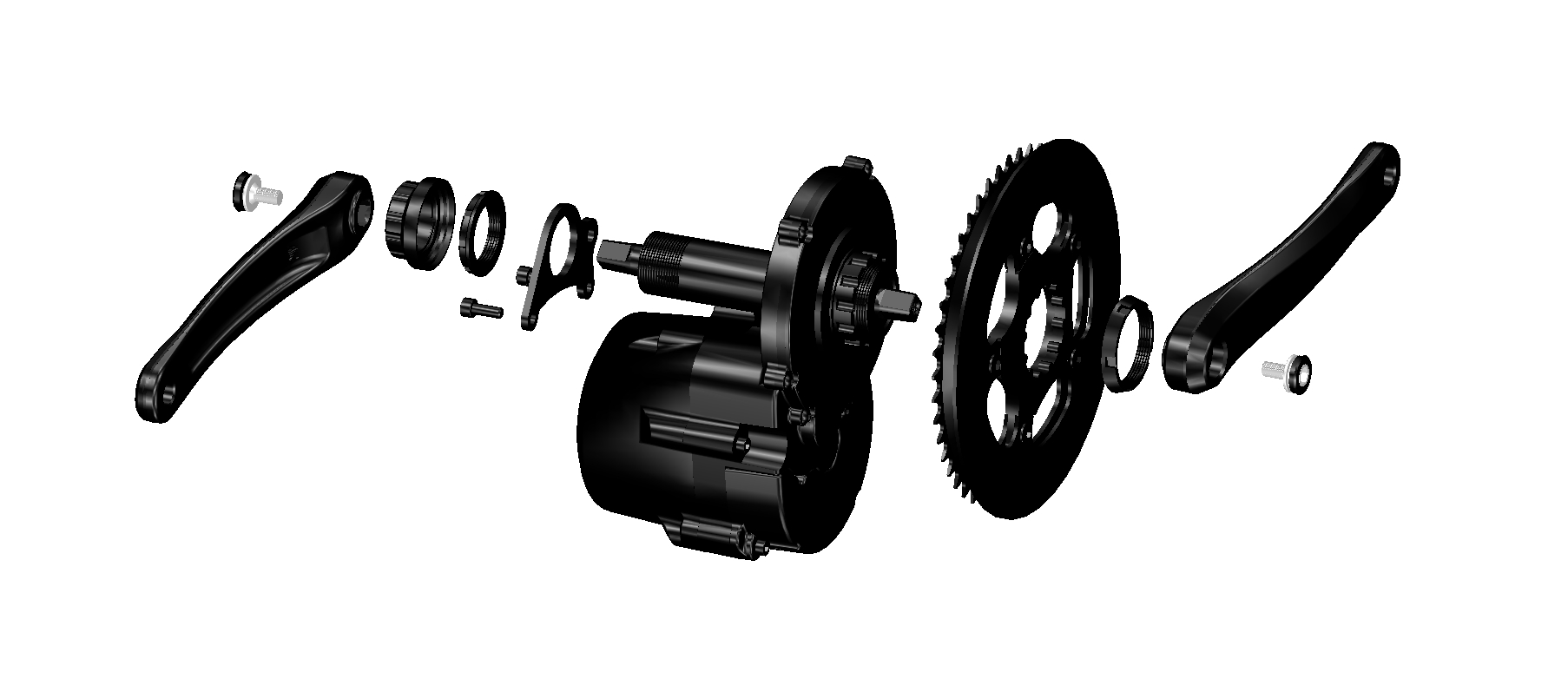

① BB=68-73 DM01-1000 DM01-750

| Component Part | Specification | Qty | BB=68 | BB=73 |

|---|---|---|---|---|

| Axle Screw | M8X1X15 | 2 | √ | √ |

| Left Crank | 170mm | 1 | √ | √ |

| Decoration Cap | 1 | √ | √ | |

| Non-standard Nut | M33.5X1.5 | 1 | √ | √ |

| Screw | See Column 4 or 5 | 2 | M6X16 | M6X20 |

| Reinforced Plates | 1 | √ | √ | |

| Drive Unit | DM01-1000 or DM01-750 | 1 | √ | √ |

| Crankset | 46T | 1 | √ | √ |

| Locknut | M42X1.5 | 1 | √ | √ |

| Right Crank | 170mm | 1 | √ | √ |

| Bushing | See Column 5 | 2 | × | Φ6X5 |

② BB=100-120 DM01L-1000 DM01L-750 DM01LA-1000 DM01LA-750

| Component Part | Specification | Qty | BB=100 | BB=110 | BB=120 |

|---|---|---|---|---|---|

| Axle Screw | M8X1X15 | 2 | √ | √ | √ |

| Left Crank | 170mm | 1 | √ | √ | √ |

| Decoration Cap | 1 | √ | √ | × | |

| Non-standard Nut | M33.5X1.5 | 1 | √ | √ | √ |

| Screw | See Column 4 or 5 | 2 | M6X50 | M6X60 | M6X70 |

| Reinforced Plates | 1 | √ | √ | √ | |

| Drive Unit | DM01L-1000 or DM01L-750 | 1 | √ | √ | √ |

| Crankset | 46T | 1 | √ | √ | √ |

| Locknut | M42X1.5 | 1 | √ | √ | √ |

| Right Crank | 170mm | 1 | √ | √ | √ |

| Lock Washer | See Column 5 | 2 | Φ6X32 | Φ6X42 | Φ6X52 |

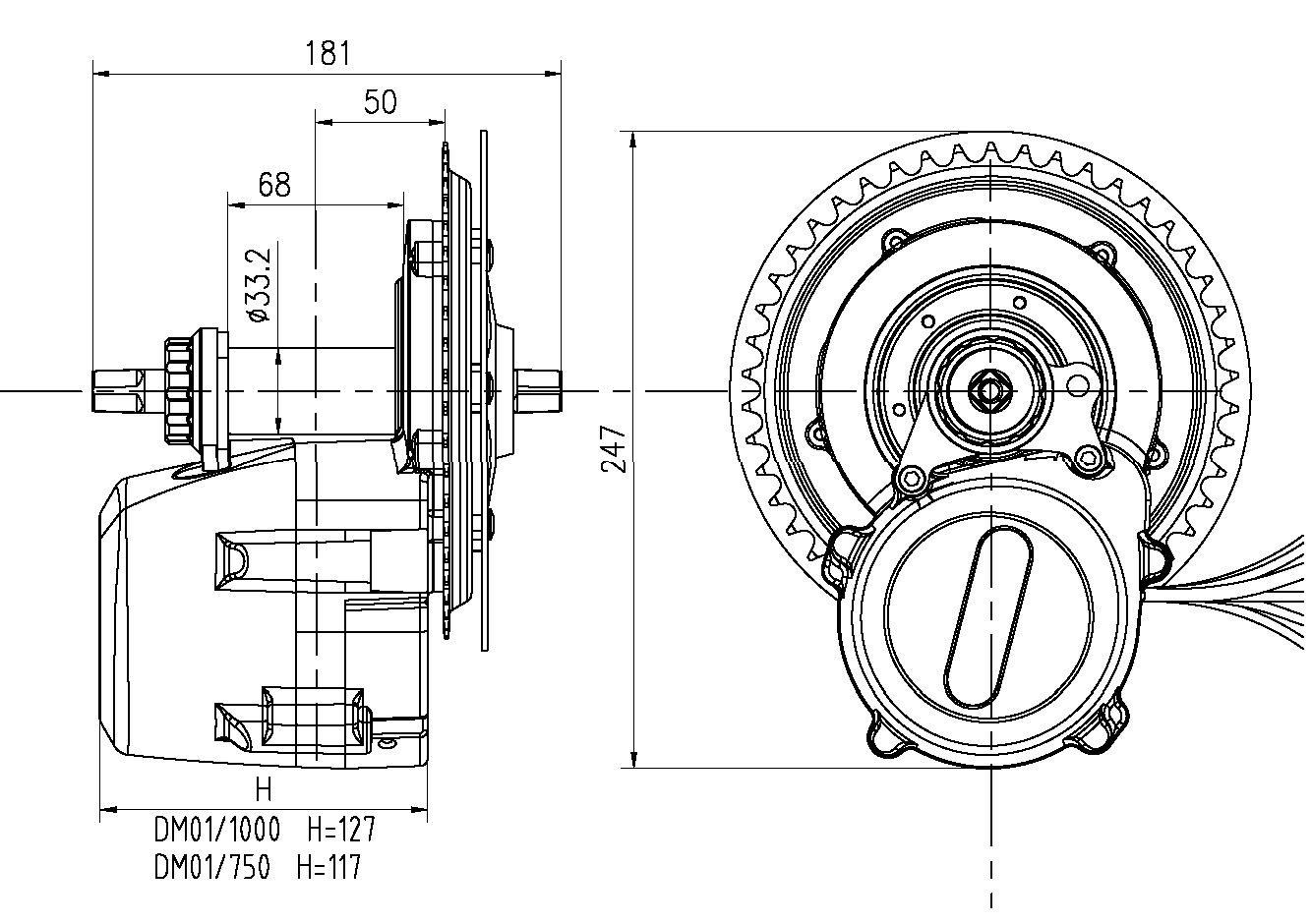

① BB=68 CL=50 (or 59)

Model: DM01-1000 DM01-750

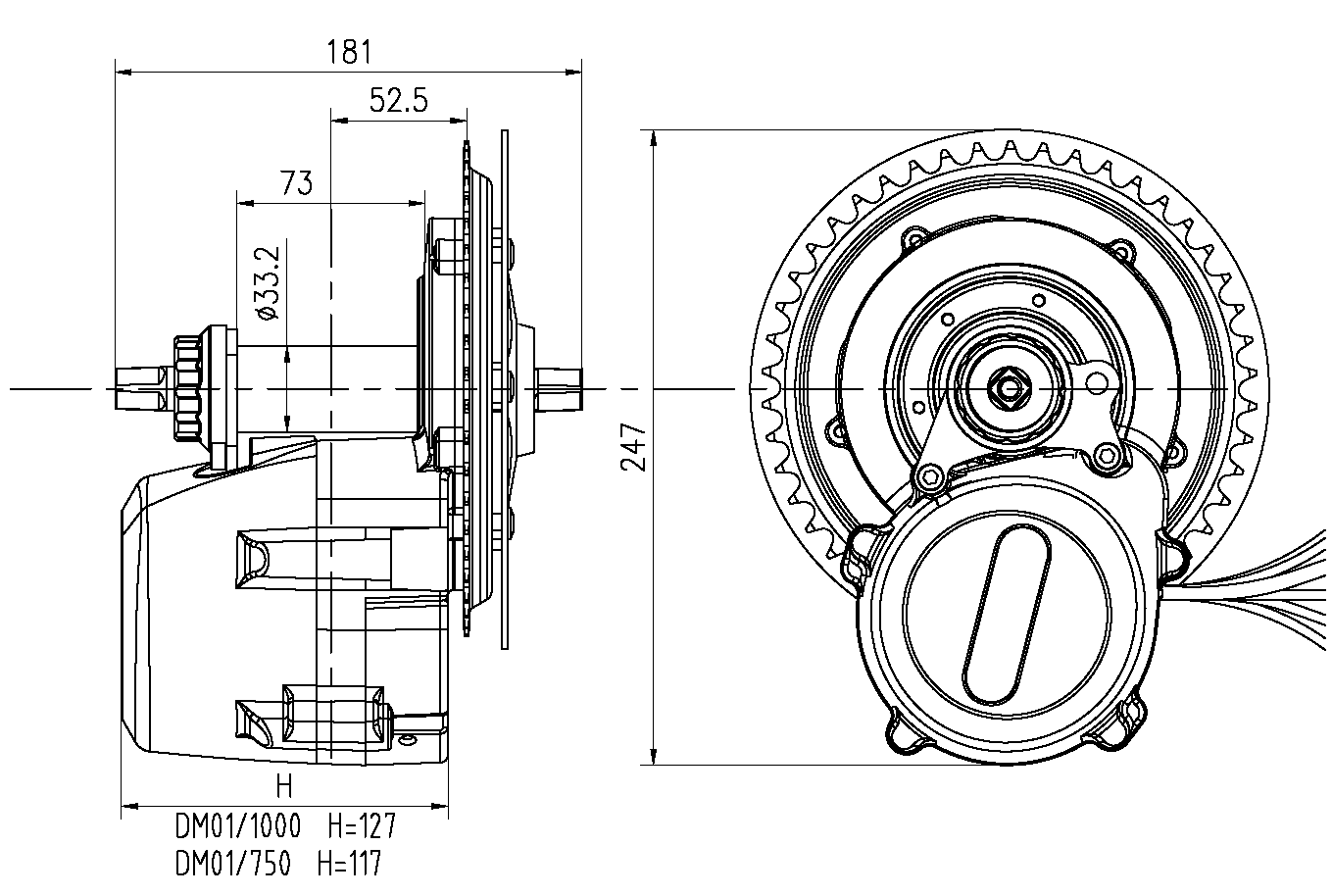

② BB=73 CL=52.5 (or 61.5)

Model: DM01-1000 DM01-750

② BB=73 CL=52.5 (or 61.5)

Model: DM01-1000 DM01-750

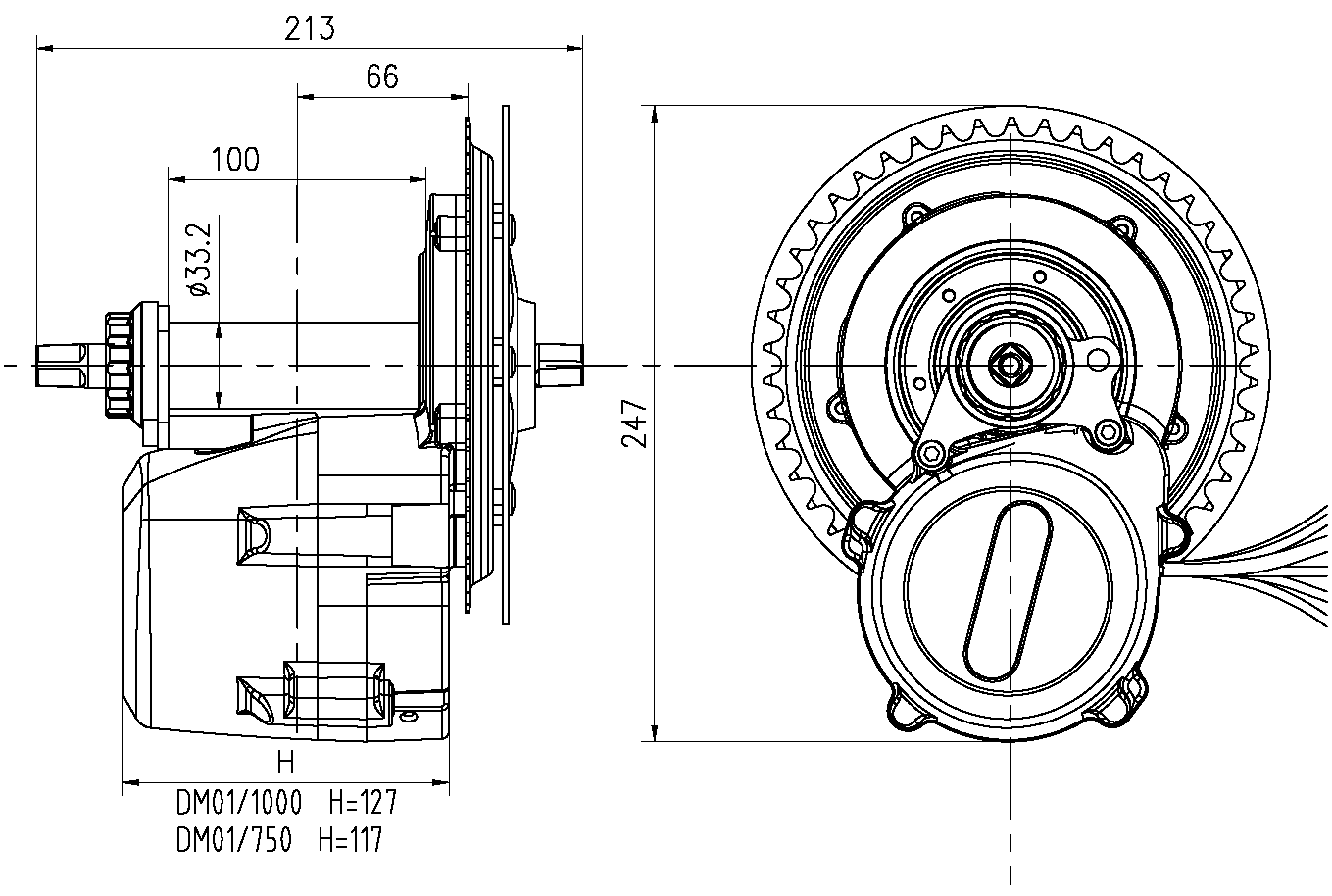

③ BB=100 CL=66 (or 75)

Model: DM01L-1000 DM01L-750

③ BB=100 CL=66 (or 75)

Model: DM01L-1000 DM01L-750

④ BB=110 CL=71 (or 80)

Model: DM01L-1000 DM01L-750

④ BB=110 CL=71 (or 80)

Model: DM01L-1000 DM01L-750

④ BB=120 CL=76 (or 85)

Model: DM01LA-1000 DM01LA-750

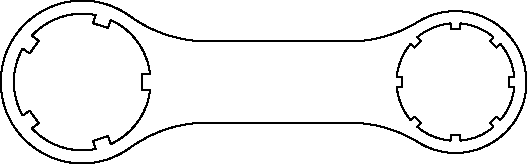

1) Installation Tool

① Special wrench:

② General tools: 6mm Allen wrench

8mm Allen wrench

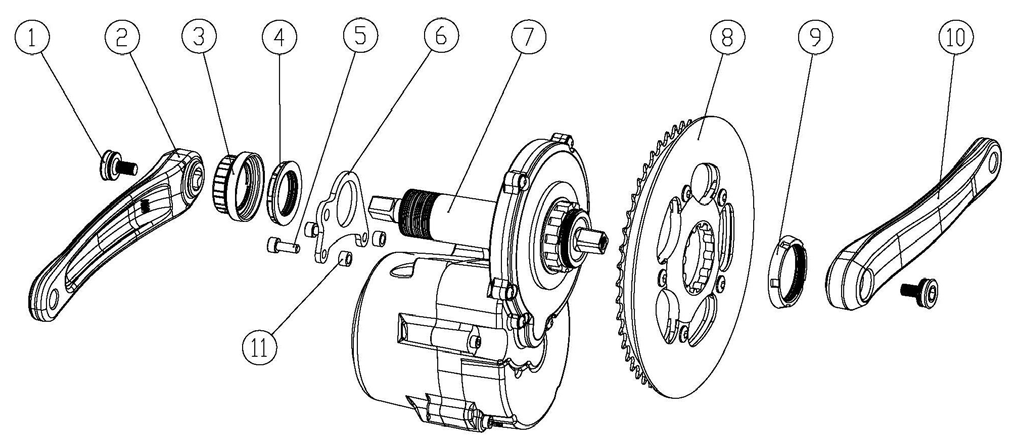

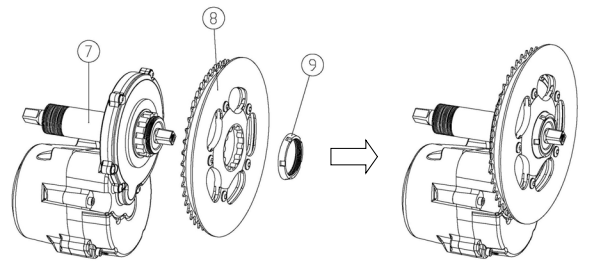

2) Cranket Mounting

- Tools: Special wrench

- Operation: Align the internal splines of the cranket 8 with the external

splines of the motor 7, press firmly to the end. Then tighten the lock nut 9,

counterclockwise with a special wrench with a tightening torque of 15Nm

- Diagram:

② General tools: 6mm Allen wrench

8mm Allen wrench

2) Cranket Mounting

- Tools: Special wrench

- Operation: Align the internal splines of the cranket 8 with the external

splines of the motor 7, press firmly to the end. Then tighten the lock nut 9,

counterclockwise with a special wrench with a tightening torque of 15Nm

- Diagram:

3) Motor Mounting

- Insert the mid-drive motor through bottom bracket from right side of the bicycle

frame and push it all the way

3) Motor Mounting

- Insert the mid-drive motor through bottom bracket from right side of the bicycle

frame and push it all the way

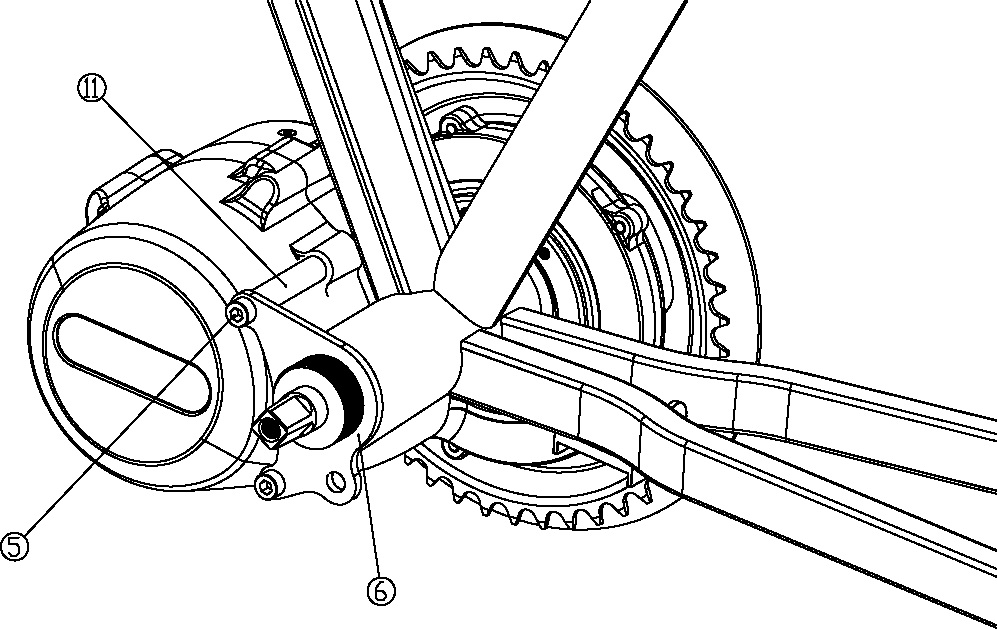

- Reinforcement Plate Mounting

- Tools: 6mm Allen Wrench

- Components(see: factory configuration):Reinforcement plate 6、M6 screw 5、

washer or bushing 11

-Requirement: Screw tightening torque 9-10Nm

-Diagram:

- BB=68

- Reinforcement Plate Mounting

- Tools: 6mm Allen Wrench

- Components(see: factory configuration):Reinforcement plate 6、M6 screw 5、

washer or bushing 11

-Requirement: Screw tightening torque 9-10Nm

-Diagram:

- BB=68

- BB=73

- BB=73

- BB=100~120

- BB=100~120

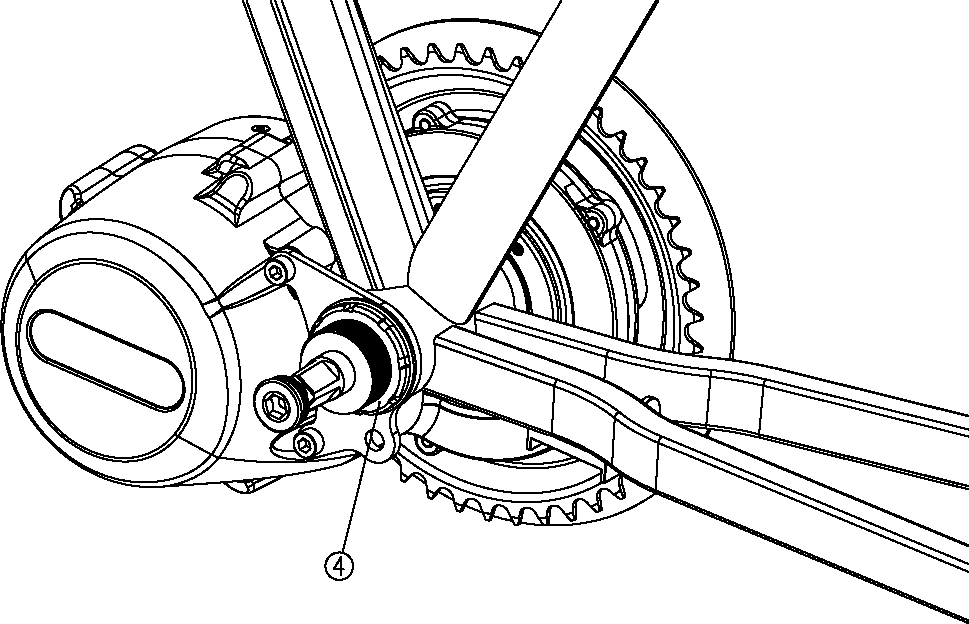

③ Non-standard nuts installation

-Tools: Special wrench

-Components(see: factory configuration):non-standard nut 4

-Requirement: before tightening the nut, turn the motor clockwise until the

motor is close to the lower tube of the frame and does not turn until it

stops, then use a special wrench to tighten the nut, torque is 45-50Nm when

tightening

-Diagram:

③ Non-standard nuts installation

-Tools: Special wrench

-Components(see: factory configuration):non-standard nut 4

-Requirement: before tightening the nut, turn the motor clockwise until the

motor is close to the lower tube of the frame and does not turn until it

stops, then use a special wrench to tighten the nut, torque is 45-50Nm when

tightening

-Diagram:

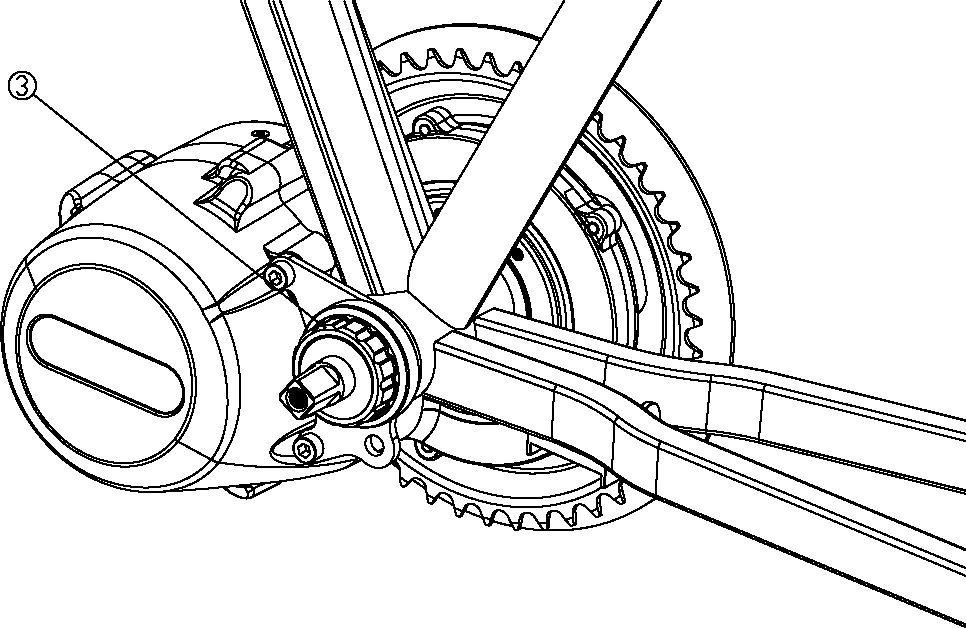

④ Decoration cap installation

- Components(see: factory configuration):decoration cap 3

- Operation: turn the decoration cap clockwise to the end by hand

- Diagram:

④ Decoration cap installation

- Components(see: factory configuration):decoration cap 3

- Operation: turn the decoration cap clockwise to the end by hand

- Diagram:

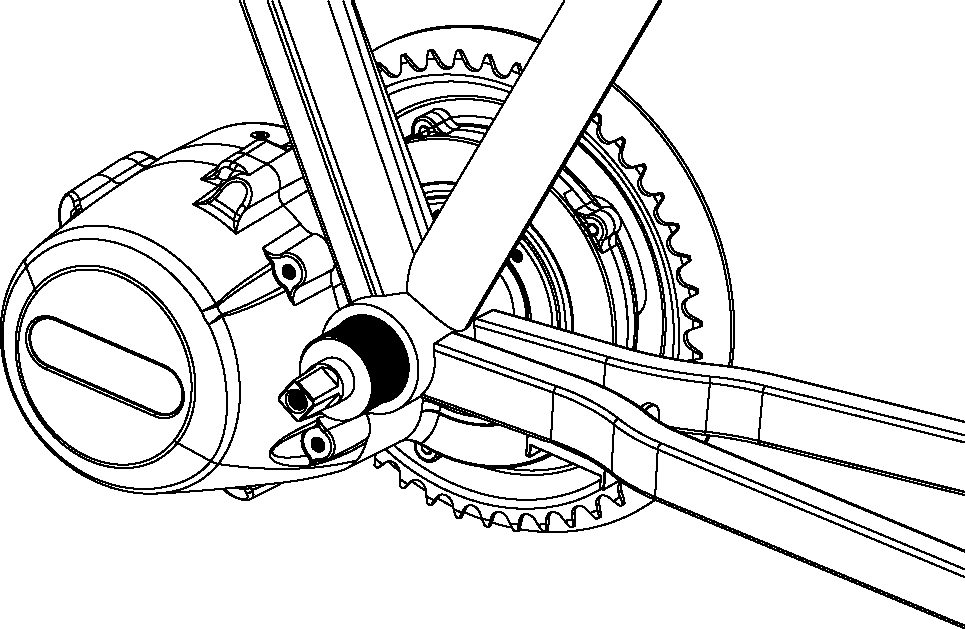

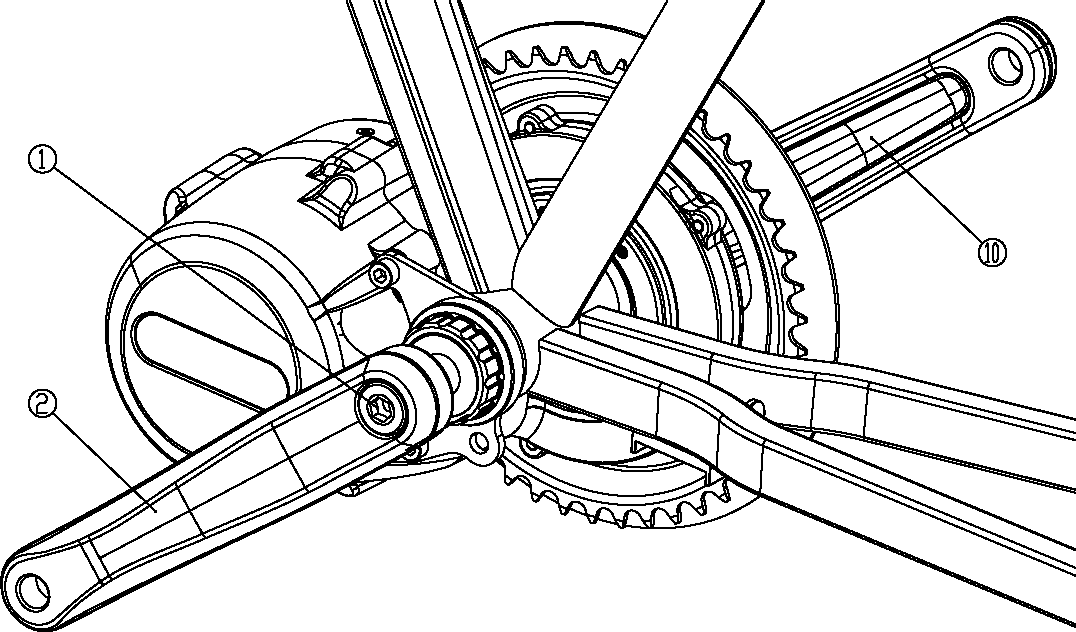

⑤ Crank Installation

-Tool: 8mm Allen wrench

-Components(see: factory configuration):axle screw 1、left crank 2、

right crank 10

- Requirement: central axle screw locking torque is 35-40Nm

-Diagram:

⑤ Crank Installation

-Tool: 8mm Allen wrench

-Components(see: factory configuration):axle screw 1、left crank 2、

right crank 10

- Requirement: central axle screw locking torque is 35-40Nm

-Diagram:

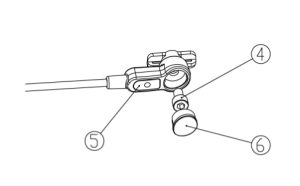

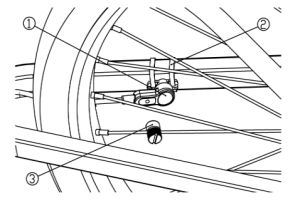

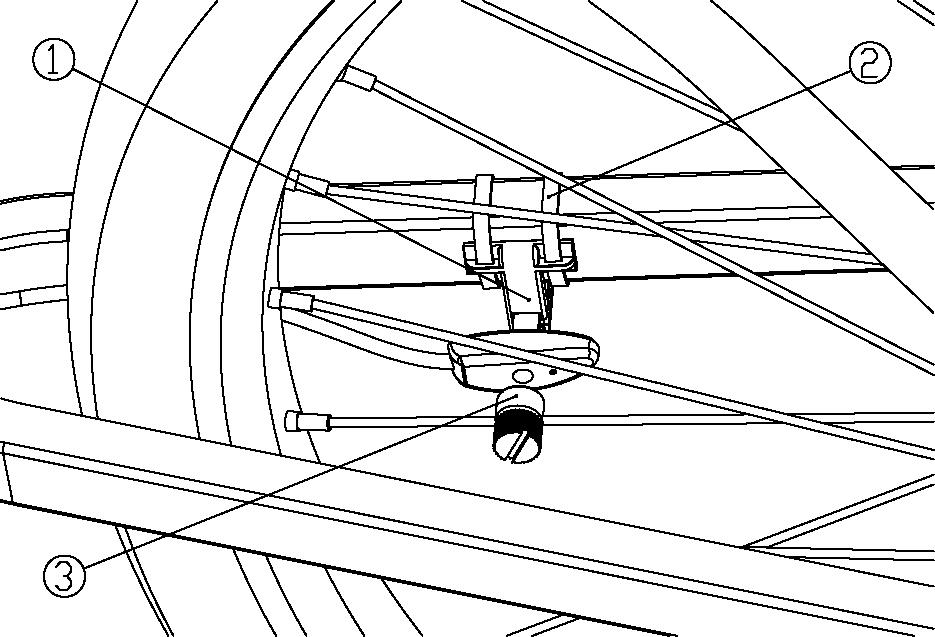

4. Speed Sensor Mounting: (MODEL:SVS1 and SVS2)

① Required Tools:

- Slotted screwdriver (5-8mm)

- Phillips screwdriver (3-5mm)

- 4mm Allen wrench

- Scissors

② Sensor Mounting:

- Secure the sensor to the bicycle fork using two cable ties. Ensure

the sensor is positioned comfortably within the designated area.

Magnet Installation:

- Using a slotted screwdriver, attach the magnets to the spokes of

your wheel.

- Alignment is crucial: During installation, ensure the flat surface

of the magnet where the magnetic field is strongest aligns

directly with the circular mark on the sensor.

③ Sensor Calibration

Model: SVS1

- Sensor Adjustment: Locate the screws on the sensor using a Phillips

screwdriver. Loosen these screws slightly.

- Distance Optimization: While holding the sensor in place, carefully

move it to achieve a distance of 2-5mm between the circular mark

on the sensor and the flat surface of the magnet (often where the

magnetic field is strongest).

- Secure the Sensor: Once the optimal distance is achieved, tighten

the screws securely using the Phillips screwdriver.

Model: SVS2

- Distance Information: This sensor model does not allow for

distance adjustment between the sensor and the magnet.

- Maximum Distance: Proper functionality can still be achieved as

long as the distance between them remains within 15mm.

④ Diagram:

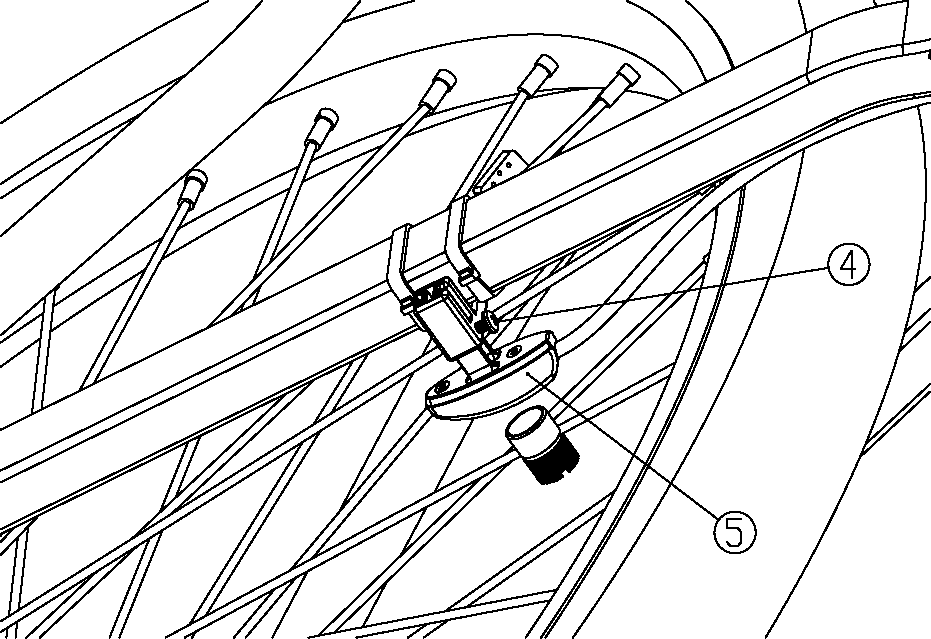

4. Speed Sensor Mounting: (MODEL:SVS1 and SVS2)

① Required Tools:

- Slotted screwdriver (5-8mm)

- Phillips screwdriver (3-5mm)

- 4mm Allen wrench

- Scissors

② Sensor Mounting:

- Secure the sensor to the bicycle fork using two cable ties. Ensure

the sensor is positioned comfortably within the designated area.

Magnet Installation:

- Using a slotted screwdriver, attach the magnets to the spokes of

your wheel.

- Alignment is crucial: During installation, ensure the flat surface

of the magnet where the magnetic field is strongest aligns

directly with the circular mark on the sensor.

③ Sensor Calibration

Model: SVS1

- Sensor Adjustment: Locate the screws on the sensor using a Phillips

screwdriver. Loosen these screws slightly.

- Distance Optimization: While holding the sensor in place, carefully

move it to achieve a distance of 2-5mm between the circular mark

on the sensor and the flat surface of the magnet (often where the

magnetic field is strongest).

- Secure the Sensor: Once the optimal distance is achieved, tighten

the screws securely using the Phillips screwdriver.

Model: SVS2

- Distance Information: This sensor model does not allow for

distance adjustment between the sensor and the magnet.

- Maximum Distance: Proper functionality can still be achieved as

long as the distance between them remains within 15mm.

④ Diagram:

MODEL: SVS1

1-Sensor 2-Tie 3-Magnet 4-Screw 5-Receiver

MODEL: SVS2

1-Speed sensor 2-Cable tie 3-Magnet 4-ScrewM5X8 5-Receiver 6-Plastic cap

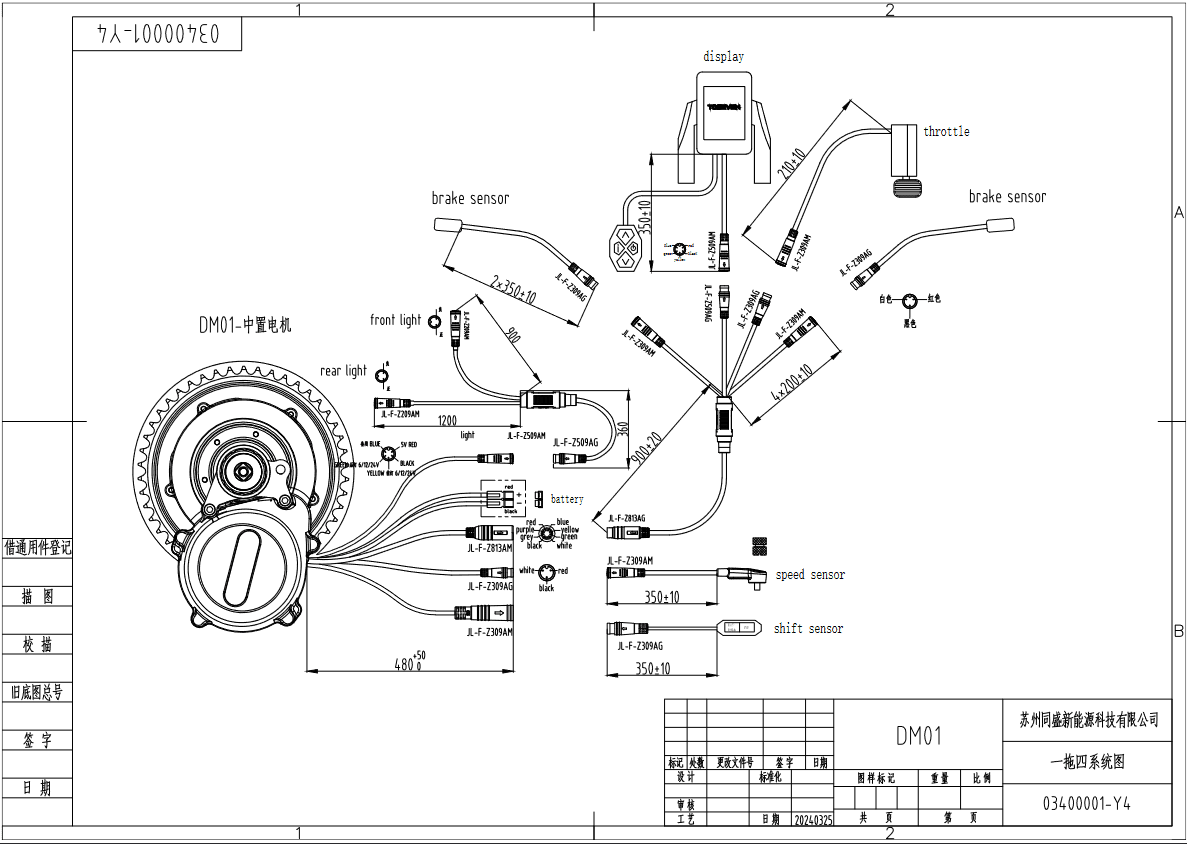

5) Wiring ① Basic Required Components: - Display(Specialized or optional) - Battery(user-provided) - Speed sensor(Specialized) - EB-Bus cable(Specialized or optional) ② Motor Connections: Carefully plug the EB-Bus cable, battery, and speed sensor connectors to their corresponding connectors on the motor. The other ends of the EB-Bus cable connectors can be plugged into the display, brake lever or brake sensor, throttle, etc. ③ Cable Routing Recommendation: To ensure optimal performance and longevity of the cables, we kindly recommend avoiding routing all cables through the narrow space between the motor and the frame. This will help prevent the cables from being pinched or damaged. Warranty: 1) Products are warranted for 12 months from the date of purchase invoice issued to the end customer, if can not provide the purchase invoice then no more than 15 months from the date of product production. 2)The warranty rights shall not be transferred to third parties (except as agreed by both parties). 3) This warranty does not mean that seller's products are not free from damage or permanent use. Compatibility: Due to different communication protocols, our motors can only be used with the accompanying accessories we provide and are not compatible with accessories from other brands. Using unauthorized accessories can cause damage to our motors and displays, and we will be unable to provide any after-sales support. ATTENTION: WARRANTY VOID IF SEAL IS REMOVED

② BB=73 CL=52.5 (or 61.5)

Model: DM01-1000 DM01-750

② BB=73 CL=52.5 (or 61.5)

Model: DM01-1000 DM01-750

③ BB=100 CL=66 (or 75)

Model: DM01L-1000 DM01L-750

③ BB=100 CL=66 (or 75)

Model: DM01L-1000 DM01L-750

④ BB=110 CL=71 (or 80)

Model: DM01L-1000 DM01L-750

④ BB=110 CL=71 (or 80)

Model: DM01L-1000 DM01L-750

② General tools: 6mm Allen wrench

8mm Allen wrench

2) Cranket Mounting

- Tools: Special wrench

- Operation: Align the internal splines of the cranket 8 with the external

splines of the motor 7, press firmly to the end. Then tighten the lock nut 9,

counterclockwise with a special wrench with a tightening torque of 15Nm

- Diagram:

② General tools: 6mm Allen wrench

8mm Allen wrench

2) Cranket Mounting

- Tools: Special wrench

- Operation: Align the internal splines of the cranket 8 with the external

splines of the motor 7, press firmly to the end. Then tighten the lock nut 9,

counterclockwise with a special wrench with a tightening torque of 15Nm

- Diagram:

3) Motor Mounting

- Insert the mid-drive motor through bottom bracket from right side of the bicycle

frame and push it all the way

3) Motor Mounting

- Insert the mid-drive motor through bottom bracket from right side of the bicycle

frame and push it all the way

- Reinforcement Plate Mounting

- Tools: 6mm Allen Wrench

- Components(see: factory configuration):Reinforcement plate 6、M6 screw 5、

washer or bushing 11

-Requirement: Screw tightening torque 9-10Nm

-Diagram:

- BB=68

- Reinforcement Plate Mounting

- Tools: 6mm Allen Wrench

- Components(see: factory configuration):Reinforcement plate 6、M6 screw 5、

washer or bushing 11

-Requirement: Screw tightening torque 9-10Nm

-Diagram:

- BB=68

- BB=73

- BB=73

④ Decoration cap installation

- Components(see: factory configuration):decoration cap 3

- Operation: turn the decoration cap clockwise to the end by hand

- Diagram:

④ Decoration cap installation

- Components(see: factory configuration):decoration cap 3

- Operation: turn the decoration cap clockwise to the end by hand

- Diagram:

⑤ Crank Installation

-Tool: 8mm Allen wrench

-Components(see: factory configuration):axle screw 1、left crank 2、

right crank 10

- Requirement: central axle screw locking torque is 35-40Nm

-Diagram:

⑤ Crank Installation

-Tool: 8mm Allen wrench

-Components(see: factory configuration):axle screw 1、left crank 2、

right crank 10

- Requirement: central axle screw locking torque is 35-40Nm

-Diagram:

4. Speed Sensor Mounting: (MODEL:SVS1 and SVS2)

① Required Tools:

- Slotted screwdriver (5-8mm)

- Phillips screwdriver (3-5mm)

- 4mm Allen wrench

- Scissors

② Sensor Mounting:

- Secure the sensor to the bicycle fork using two cable ties. Ensure

the sensor is positioned comfortably within the designated area.

Magnet Installation:

- Using a slotted screwdriver, attach the magnets to the spokes of

your wheel.

- Alignment is crucial: During installation, ensure the flat surface

of the magnet where the magnetic field is strongest aligns

directly with the circular mark on the sensor.

③ Sensor Calibration

Model: SVS1

-

4. Speed Sensor Mounting: (MODEL:SVS1 and SVS2)

① Required Tools:

- Slotted screwdriver (5-8mm)

- Phillips screwdriver (3-5mm)

- 4mm Allen wrench

- Scissors

② Sensor Mounting:

- Secure the sensor to the bicycle fork using two cable ties. Ensure

the sensor is positioned comfortably within the designated area.

Magnet Installation:

- Using a slotted screwdriver, attach the magnets to the spokes of

your wheel.

- Alignment is crucial: During installation, ensure the flat surface

of the magnet where the magnetic field is strongest aligns

directly with the circular mark on the sensor.

③ Sensor Calibration

Model: SVS1

-