This guide covers TO7Motor’s complete hub motor lineup: 38 different models organized into strategic platforms based on real-world use.

Why Hub Motor Selection Actually Matters

- Dropout compatibility issues – Your frame has a specific spacing (100mm to 190mm+), and the motor must match exactly

- Gear system mismatches – A cassette motor won’t work with a freewheel setup and vice versa.

- Insufficient torque – Wattage doesn’t equal hill-climbing ability; reduction ratios and torque matter more

- Voltage constraints: Your battery voltage must be within the motor’s rated voltage range.

- Weight penalties – Heavier motors affect handling, especially on front wheels.

Understanding the Platform Architecture

Platform I: Heavy-Duty Cargo & Fat Bike Power (D79 Series)

High torque, wide dropouts, built for serious loads and challenging terrain.

Platform II: Regulated Urban & Mid-Power (D7 + S7 Series)

Balanced performance optimized for EU/US regulations and city riding with moderate cargo capability.

Platform III: Versatile Commuter & Light Utility (B7 + K7 Series)

Flexible options for standard commuter builds, folding bikes, and urban touring.

Platform IV: Ultra-Compact & Specialized (E7, C7, A7, L7 Series)

Lightweight internal rotor designs, single-sided mounting, wheelchair motors, and internal gear systems.

ZM05-175DL – The Ultimate Power Option

The Power Statement

Radical Electromagnetic Architecture

Stator Core Engineering:

- 195mm stator diameter made from 3mm-thick, 45-grade high-magnetic steel

- This massive core allows for superior heat dissipation and sustained high-power output

- The thick steel laminations reduce eddy current losses and improve magnetic flux density

Magnet Configuration:

- 23 pole pairs (46 individual magnets) for massive low-end torque

- High pole count means smoother power delivery and better torque at low speeds

- Ideal for cargo applications where you need pulling power from a standstill

Performance Metrics:

- 860 RPM no-load speed

- 82% peak efficiency

- 72V capable, 4000W peak power

Physical Specifications

Dropout & Mounting:

- 175mm dropout spacing (fat-tire ready)

- Heavy-duty M16 x 1.5 axle for extreme load applications

- 6-hole disc brake mount

- 195mm core diameter

Weight:

- 9.4 kg

- Yes, it’s heavy—but this weight comes with structural integrity and thermal mass for sustained high-power operation

- When you’re hauling 180kg of cargo up a 25° grade, weight becomes irrelevant

| Specification | Value |

|---|---|

| Model | ZM05-175DL |

| Rated Power | 3000W |

| Peak Power | 4000W |

| Max Torque | 120 N·m |

| Open Size | 175mm |

| Weight | 9.4 kg |

| Efficiency | 82% |

| Voltage Range | 60-72V |

| Application | High-speed fat bikes, extreme cargo, commercial trike |

Who Should Choose ZM05-175DL:

- Commercial trike operators

- High-speed off-road builds (where legal)

- Extreme terrain riders (Arctic, desert, mountain)

- Heavy commercial cargo applications

- Custom builds requiring maximum power.

Platform I: Heavy-Duty Cargo & Fat Bike Power

D79 Series – The Workhorse Platform

When you need to move serious weight—whether that’s cargo, passengers, or yourself up a 15% grade—the D79 series delivers.

These are 1000W-2000W motors with 110 N·m of torque, engineered for e-cargo bikes, heavy-duty fat bikes, and utility applications.

| Model | Position | Open Size | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| D79-140QL | Front | 140mm | None (disc brake) | 48-72V | 1000-2000W | 110 N·m | 5.9 kg |

| D79-175XL | Rear | 175mm | 6-7 speed freewheel | 48-72V | 1000-2000W | 110 N·m | 6.0 kg |

| D79-175KL | Rear | 175mm | 8-10 speed cassette | 48-72V | 1000-2000W | 110 N·m | 6.1 kg |

| D79-175PL | Rear | 175mm | Single belt pulley | 48-72V | 1000-2000W | 110 N·m | 6.1 kg |

| D79-190KL | Rear | 190mm | 8-10 speed cassette | 48-72V | 1000-2000W | 110 N·m | 6.2 kg |

Key Technical Features:

- Reduction ratio: 5.8:1 (optimized for low-speed torque)

- 16 magnets + 16-sensor speed detection

- 36H spoke holes with 13G/12G compatibility

- IP65 waterproof rating

- <55dB noise level

- ≥80% efficiency

Who Should Choose D79:

- Cargo bike builders hauling 100+ lbs regularly.

- Fat bike riders tackling snow, sand, or mud

- Delivery fleet operators

- Riders in hilly terrain who need sustained climbing power

- Anyone converting a bike for commercial use.

Real-World Scenario: You’re building a longtail cargo bike to replace your second car for kid drop-offs and grocery runs.

You live in a hilly area and regularly carry 150 lbs of cargo. The D79-175KL (cassette version for modern drivetrains) or D79-175XL (freewheel for budget builds) gives you the torque to climb loaded without overheating.

Platform II: Regulated Urban & Performance

D7 Series – Smart Compliance with Real Power

The D7 series bridges the gap between regulatory compliance and genuine performance.

These 350W-750W motors use a clever 7.77:1 reduction ratio on cassette models (5.15:1 on freewheel versions) to deliver 90 N·m of torque—perfect for EU 250W regulations and US urban markets.

| Model | Position | Open Size | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| D7-135QL | Front | 135mm | None (disc brake) | 36-52V | 350-750W | 90 N·m | 3.8 kg |

| D7-175XL | Rear | 175mm | 6-7 speed freewheel | 36-52V | 350-750W | 90 N·m | 4.0 kg |

| D7-190XL | Rear | 190mm | 6-7 speed freewheel | 36-52V | 350-750W | 90 N·m | 4.0 kg |

| D7-175KL | Rear | 175mm | 8-10 speed cassette | 36-52V | 350-750W | 90 N·m | 4.2 kg |

Key Technical Features:

- Higher reduction ratio (7.77:1 on cassette models) for superior low-speed torque

- 20 magnets for smoother power delivery

- 36H spoke configuration

- Max speed: 40-50 km/h, depending on voltage

- IP65 protection

- ≥80% efficiency

Who Should Choose D7:

- EU riders needing 250W-compliant motors with real climbing ability

- Urban cargo bike builders (lighter loads than D79)

- Riders wanting strong hill performance without the weight of D79.

- Fleet operators in regulated markets

Real-World Scenario: You run a bike-share program in Berlin. You need motors that comply with EU 250W regulations, but can still handle riders going up bridges with groceries.

The D7-175KL delivers legal compliance with enough torque that users don’t feel underpowered.

S7 Series – Balanced Utility Performance

The S7 series offers 75 N·m of torque in a lighter, more efficient package (3.9-4.2 kg).

These are excellent for moderate cargo, urban commuting, and riders who want good performance without maximum power.

| Model | Position | Open Size | Cable Routing | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|---|

| S7-175XL | Rear | 175mm | Side-left | 6-7 speed freewheel | 36-52V | 350-750W | 75 N·m | 3.9 kg |

| S7-190XL | Rear | 190mm | Side-left | 6-7 speed freewheel | 36-52V | 350-750W | 75 N·m | 4.2 kg |

| S7-175XR | Rear | 175mm | Axle-right | 6-7 speed freewheel | 36-52V | 350-750W | 75 N·m | 3.9 kg |

| S7-190XR | Rear | 190mm | Axle-right | 6-7 speed freewheel | 36-52V | 350-750W | 75 N·m | 4.2 kg |

Key Technical Features:

- Reduction ratio: 5.15:1

- 20 magnets

- Multiple cable routing options (side-left or axle-right)

- Max speed: 32-45 km/h

- IP65 protection

Who Should Choose S7:

- Urban riders with occasional cargo needs

- Commuters want a reliable daily performance.

- Budget-conscious builders (lighter weight = less expensive batteries)

- Riders in moderately hilly areas

Cable Routing Explained: “XL” models route the cable out the left side of the axle, while “XR” models route it through the right side of the axle.

Choose based on your frame’s cable management design.

Platform III: Versatile Commuter & Light Utility

B7 Series – The Flexibility Champion

The B7 series offers the widest range of dropouts (100mm to 190mm), with 75 N·m of torque and a 7.77:1 reduction ratio.

These motors excel at urban commuting, light touring, and micro-MTB builds.

| Model | Position | Open Size | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| B7-100QR | Front | 100mm | None (disc brake) | 36-48V | 350-500W | 75 N·m | 3.3 kg |

| B7-138XL | Rear | 138mm | 6-7 speed freewheel | 36-48V | 350-500W | 75 N·m | 3.5 kg |

| B7-138XR | Rear | 138mm | 6-7 speed freewheel | 36-48V | 350-500W | 75 N·m | 3.5 kg |

| B7-145KL | Rear | 145mm | 8-10 speed cassette | 36-48V | 350-500W | 75 N·m | 3.8 kg |

| B7-145XL | Rear | 145mm | 6-7 speed freewheel | 36-48V | 350-500W | 75 N·m | 3.5 kg |

| B7-145XR | Rear | 145mm | 6-7 speed freewheel | 36-48V | 350-500W | 75 N·m | 3.5 kg |

| B7-190CS | Rear | 190mm | Differential (trike) | 36-52V | 350-750W | 75 N·m | 3.5 kg |

Key Technical Features:

- 16 magnets

- 36H spoke configuration

- Max speed: 32-45 km/h

- Lighter weight than D7/S7 (3.3-3.8 kg)

- IP65 protection

Who Should Choose B7:

- Daily urban commuters

- Riders with standard bicycle frames (not cargo-specific)

- Trike builders (B7-190CS with differential)

- Micro mountain bike conversions

- Anyone wanting solid performance without excess weight

K7 Series – Compact Commuter Excellence

The K7 series prioritizes lightweight portability for folding bikes, compact urban builds, and city touring. These 250-350W motors weigh just 2.1-2.4 kg while delivering 45 N·m of torque.

| Model | Position | Open Size | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| K7-100QR | Front | 100mm | None (disc brake) | 24-48V | 250-350W | 45 N·m | 2.1 kg |

| K7-125DL | Rear | 125mm | Single speed | 24-48V | 250-350W | 45 N·m | 2.2 kg |

| K7-135XL | Rear | 135mm | 6-7 speed freewheel | 24-48V | 250-350W | 45 N·m | 2.3 kg |

| K7-135XR | Rear | 135mm | 6-7 speed freewheel | 24-48V | 250-350W | 45 N·m | 2.2 kg |

| K7-138KL | Rear | 138mm | 8-10 speed cassette | 24-48V | 250-350W | 45 N·m | 2.4 kg |

| K7-138KR | Rear | 138mm | 8-10 speed cassette | 24-48V | 250-350W | 45 N·m | 2.4 kg |

Key Technical Features:

- Variable reduction ratios (7.33:1 to 8.14:1)

- 16 magnets

- Wheel size compatibility: 12″ to 28″ (extremely versatile)

- Max speed: 25-35 km/h

- Extremely lightweight for easy portability

Who Should Choose K7:

- Folding bike converters

- Urban riders carrying bikes up stairs

- Commuters combining bike + public transit

- Riders prioritizing weight over maximum power

- City tourers on flat to moderate terrain

Platform IV: Ultra-Compact & Specialized Solutions

E7 Series – The Lightweight Champion

The E7 series represents TO7’s lightest motors: just 1.9 kg per unit.

These internal-rotor motors deliver 40 N·m of torque with an 11:1 reduction ratio, designed for riders who need electric assistance without the weight penalty.

| Model | Position | Open Size | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| E7-100QL | Front | 100mm | None (disc brake) | 24-48V | 250-350W | 40 N·m | 1.9 kg |

| E7-120DL | Rear | 125mm | Single speed | 24-48V | 250-350W | 40 N·m | 1.9 kg |

| E7-135KL | Rear | 135mm | 8-10 speed cassette | 24-48V | 250-350W | 40 N·m | 1.9 kg |

| E7-135XL | Rear | 135mm | 6-7 speed freewheel | 24-48V | 250-350W | 40 N·m | 1.9 kg |

Key Technical Features:

- Internal rotor design (more compact than external rotor)

- 14 magnets

- 11:1 reduction ratio

- Wheel size: 12″ to 28″

- Max speed: 25-35 km/h

Who Should Choose E7:

- Weight-obsessed riders

- Road bike converters maintaining nimble handling

- Elderly riders needing minimal assistance

- Portable commuter builds

- Anyone prioritizing natural bike feel over power.

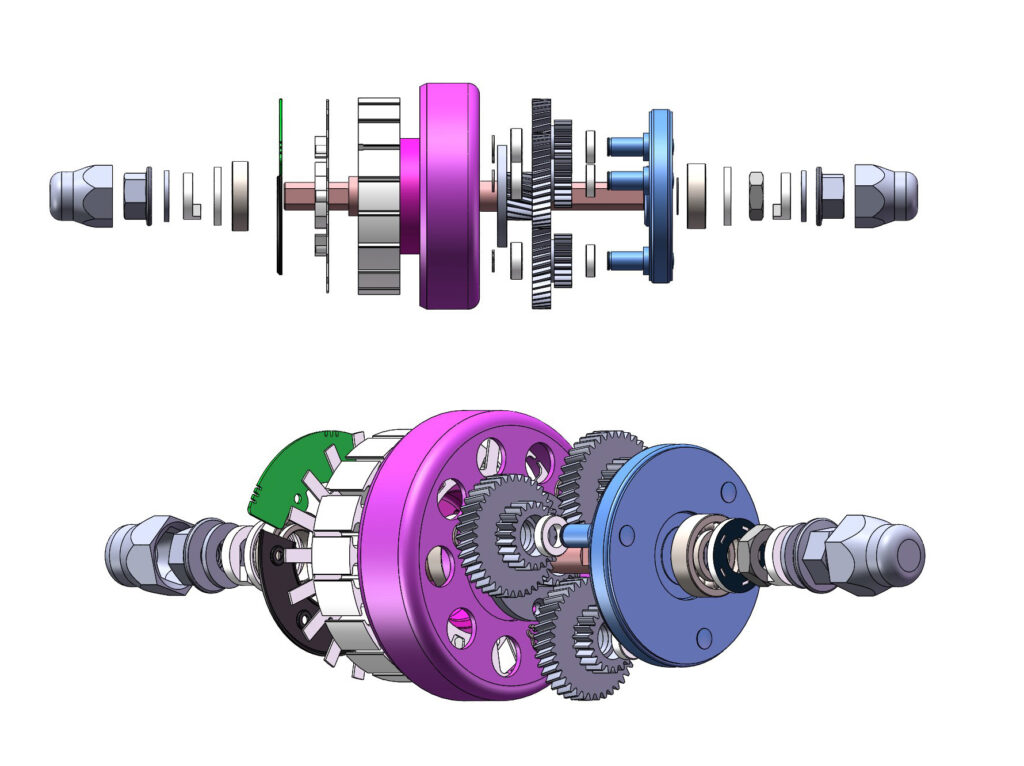

Internal Rotor Explained: Traditional hub motors mount magnets on the outside shell (external rotor).

E7 series uses magnets inside, creating a smaller, lighter package with slightly lower torque but superior weight distribution.

C7 Series – Single-Sided Mounting Innovation

| Model | Position | Open Size | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| C7-100QR | Front | 100mm | None (disc brake) | 24-48V | 250-350W | 45 N·m | 2.6 kg |

| C7-125DR | Rear | 125mm | Single speed | 24-48V | 250-350W | 45 N·m | 2.7 kg |

| C7-135XR | Rear | 135mm | 6-9 speed | 24-48V | 250-350W | 45 N·m | 2.8 kg |

| C7-158XR | Rear | 158mm | 6-7 speed freewheel | 24-48V | 250-350W | 45 N·m | 2.8 kg |

| C7-175XR | Rear | 175mm | 6-7 speed freewheel | 24-48V | 250-350W | 45 N·m | 3.1 kg |

| C7-195XR | Rear | 195mm | 6-7 speed freewheel | 24-48V | 250-350W | 45 N·m | 3.2 kg |

Key Technical Features:

- 5.16:1 reduction ratio

- 20 magnets (smoother operation)

- Axle-right cable routing for cleaner installations

- Max speed: 25-35 km/h

- IP65 protection

Who Should Choose C7:

- Fleet operators needing fast wheel swaps

- Bike-share programs

- Riders who do frequent tire maintenance

- Builders wanting cleaner cable management.

- Anyone frustrated with traditional hub motor servicing.

A7 Series – Mobility & Wheelchair Application

The A7-100YL is specifically engineered for electric wheelchair applications with dual-ratio capability (5.6:1 and 14.16:1) for both cruising and climbing.

| Model | Position | Open Size | Wheel Size | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| A7-100YL | Wheelchair wheel | 100mm | 8″ | 24-36V | 250-350W | 40 N·m | 1.9 kg |

Who Should Choose A7:

- Electric wheelchair manufacturers

- Mobility device builders

- Medical equipment OEMs

L7 Series – Internal Planetary Gear System

| Model | Position | Open Size | Drivetrain | Voltage | Rated Power | Max Torque | Weight |

|---|---|---|---|---|---|---|---|

| L7-135N | Front | 135mm | 3-speed internal | 36-48V | 250-350W | 36 N·m | 3.2 kg |

Who Should Choose L7:

- Urban riders wanting clean, maintenance-free gear shifting.

- Commuters in wet climates (internal gears protected from elements)

- Builders seeking minimalist aesthetics

- Riders prioritizing low maintenance

Technical Deep Dive: What the Specs Really Mean

Understanding Reduction Ratios

- High ratio (7.77:1, 8.14:1): More torque, lower top speed, better climbing

- Medium ratio (5.15:1, 5.8:1): Balanced torque and speed

- Low ratio (11:1 direct drive): Higher speed potential, less torque multiplication

Magnet Count and Performance

- Smoother power delivery (less cogging)

- Better low-speed torque

- Improved efficiency

- Slightly higher cost

Dropout Sizing: Getting It Right

- 100mm: Standard front wheels, compact rear (folding bikes)

- 135mm: Traditional rear road/mountain bike

- 142-145mm: Modern mountain bike “Boost” standard

- 175mm: Fat bike, cargo bike

- 190mm: Extra-wide cargo, trikes

Freewheel vs. Cassette: Know the Difference

Freewheel (6-7 speed):

- Screws directly onto hub threads

- Budget-friendly

- Easier to replace

- Common on city bikes and older mountain bikes

Cassette (8-10 speed):

- Slides onto a freehub body with splines

- Required for modern road and mountain bikes

- Better gear range

- Standard on quality bikes from the last 15 years

IP65 Waterproof Rating Explained

- 6: Complete dust protection

- 5: Water jets from any direction won’t damage internals

Why Efficiency Matters (≥80%)

- How much battery energy converts to motion vs. heat

- Real-world range per charge

- Motor temperature under sustained load

How to Choose the Right Hub Motor: FrameWork

Step 1: Determine Your Primary Use Case

Heavy Cargo/Utility (100+ lbs loads regularly):

→ D79 Series or ZM05-175DL

Urban Cargo/Commuting (occasional cargo, moderate hills):

→ D7 or S7 Series

Daily Commuting (no cargo, general assistance):

→ B7 or K7 Series

Lightweight/Portability Priority:

→ E7 or K7 Series

Specialized (wheelchair, internal gears, easy maintenance):

→ A7, L7, or C7 Series

Step 2: Measure Your Frame

- Front wheel: Usually 100mm

- Rear wheel: 135mm (standard), 142-145mm (boost MTB), 175mm (fat bike), 190mm (cargo/trike)

Step 3: Identify Your Drivetrain Type

- Freewheel: Gears screw onto the hub (usually 6-7 speeds)

- Cassette: Gears slide onto splined freehub body (8-11 speeds)

- Single speed: No gears, just one sprocket

Step 4: Voltage and Power Matching

- 24-36V systems: K7, E7, C7, A7, L7 series

- 36-48V systems: B7, D7, S7 series

- 48-72V systems: D79 series

- 60-72V systems: ZM05-175DL

Step 5: Consider Weight vs. Power Trade-offs

| Priority | Recommended Series |

|---|---|

⚡ Maximum Power Cargo, commercial, extreme use | D79 • ZM05 |

🎯 Best Torque-to-Weight High performance, manageable weight | D7 • S7 |

⚖️ Balanced Performance Versatile, all-around capability | B7 |

🍃 Lightest Possible Portability, folding bikes | E7 • K7 |

🔧 Easy Maintenance Simple servicing, single-sided | C7 |

Common Questions Answered

Q: What’s the difference between the D7 and S7 series?

The D7 has higher torque (90 N·m vs. 75 N·m) due to a more aggressive reduction ratio, but weighs slightly more (4.0-4.2 kg vs. 3.9-4.2 kg).

Choose D7 for hillier terrain or heavier riders; S7 for flatter areas where the weight savings matter more.

Q: Can I use a 1000W motor with a 500W controller?

Yes, but you’ll only get 500W of output. The motor can handle more power, but the controller limits it.

This setup gives you the potential to upgrade later.

Q: Which motor is best for hills?

Torque and reduction ratio matter more than wattage. For steep hills: D79 series (110 N·m, 5.8:1) > D7 series (90 N·m, 7.77:1) > S7 series (75 N·m, 5.15:1).

Q: Do I need a front or rear motor?

- Rear motors provide better traction (weight distribution) and feel more natural.

- Front motors let you keep your rear gears, are easier to install, and work well on flat terrain.

- Heavy cargo should use rear motors for stability.

Q: What does the “36H” specification mean?

36H = 36 spoke holes. This is standard for e-bikes and matches most rims. More spokes = stronger wheel, essential for cargo and heavy riders.

Q: Can I increase top speed by using higher voltage?

Yes, but only within the motor’s rated range.

Going from 36V to 48V on a 36-48V motor can increase the speed proportionally (generally about ~33%). Exceeding the maximum voltage damages the motor.

Q: What’s better: hub motor or mid-drive?

Hub motors (this guide): Lower maintenance, cheaper, quieter, better for flat to moderate terrain, easier DIY installation.

Mid-drives: Better climbing, more efficient on steep grades, higher cost, more maintenance. Choose based on terrain and riding style.

Specifications at a Glance: Cross-Series Comparison

| Series | Power Range | Torque | Weight Range | Best For |

|---|---|---|---|---|

| D79 | 1000-2000W | 110 N·m | 5.9-6.2 kg | Heavy cargo, commercial |

| ZM05 | 3000-4000W | 120 N·m | 9.4 kg | Extreme power needs |

| D7 | 350-750W | 90 N·m | 3.8-4.2 kg | Regulated markets, hills |

| S7 | 350-750W | 75 N·m | 3.9-4.2 kg | Urban utility, balance |

| B7 | 350-500W | 75 N·m | 3.3-3.8 kg | Commuting, versatility |

| K7 | 250-350W | 45 N·m | 2.1-2.4 kg | Folding bikes, portability |

| E7 | 250-350W | 40 N·m | 1.9 kg | Ultra-lightweight builds |

| C7 | 250-350W | 45 N·m | 2.6-3.2 kg | Easy maintenance, city |

| A7 | 250-350W | 40 N·m | 1.9 kg | Wheelchairs |

| L7 | 250-350W | 36 N·m | 3.2 kg | Internal gear systems |

Why TO7Motor: Manufacturing Quality

- OEM manufacturers across North America, Europe, Australia, and Asia

- Retail distributors stocking quality conversion kits

- DIY builders seeking reliable components

- Commercial fleet operators requiring durability

Key Quality Indicators:

- IP65 waterproof standard across all models

- ≥80% efficiency baseline

- <55dB noise control

- Consistent use of high-grade aluminum alloy shells

- Comprehensive testing protocols

- Global warranty support

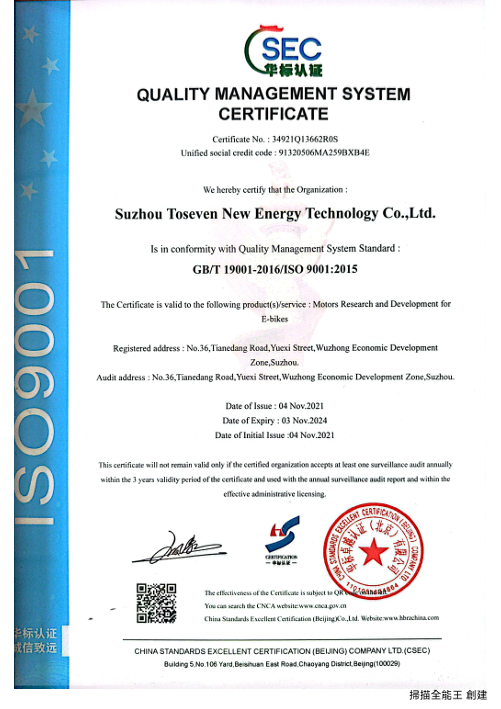

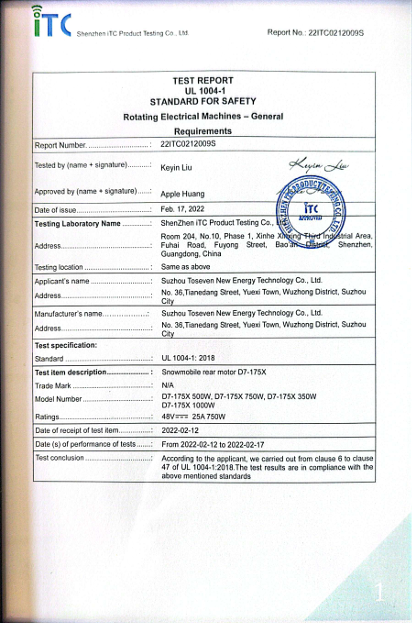

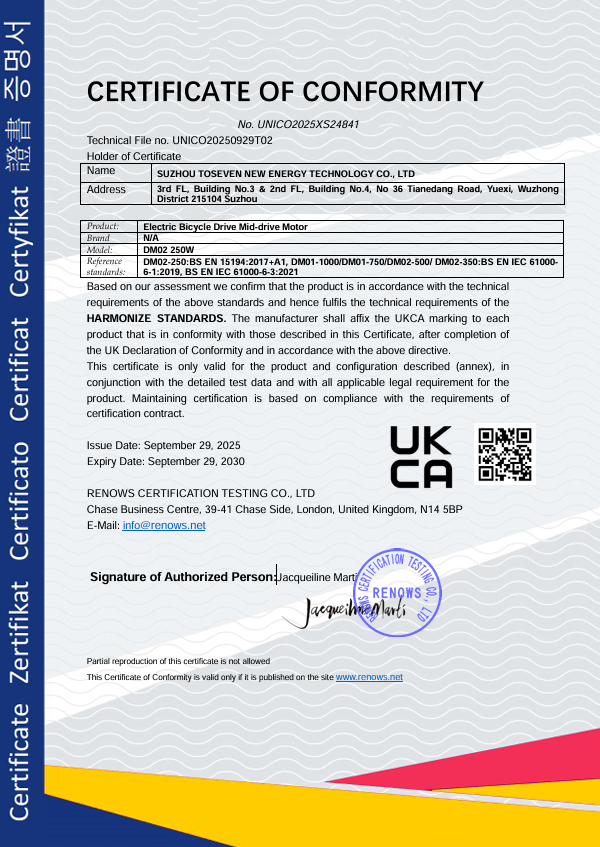

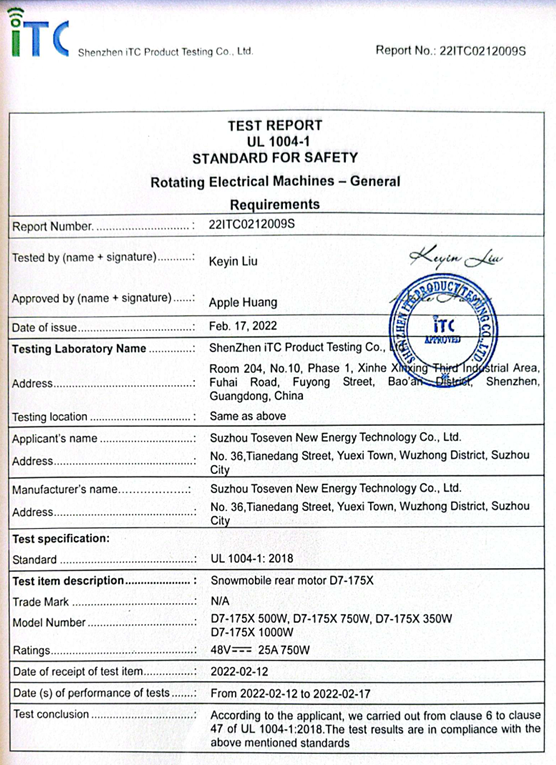

Our Certificates For Hub Motors

Final Recommendations by Rider Profile

Urban Commuter (10-20 miles daily, flat to moderate hills):

→ B7-145XL or K7-135XL (lightweight, reliable, efficient)

Cargo Parent (kid hauling, grocery runs, hilly suburbs):

→ D7-175KL or D79-175KL (depends on total load weight)

→ D79-190KL (maximum durability, highest torque)

→ K7-100QR (front wheel, ultra-light, portable)

→ D79-175XL or ZM05-175DL (depending on power needs)

→ B7-138XL or S7-175XL (good performance, moderate cost)

→ B7-145KL or D7-175KL (cassette compatibility, good torque)

→ E7-135XL or K7-135XL (gentle assist, lightweight)

If You’d Like To Get Into Deeper Technical Specifics:

Conclusion: Making the Informed Choice

- Match the dropout size exactly to your frame.

- Choose the right drivetrain type (cassette vs. freewheel)

- Select torque based on terrain (not just wattage)

- Consider weight trade-offs vs. power needs.

- Verify voltage compatibility with your battery.