What is a mid-drive conversion kit?

A mid-drive conversion kit replaces or adds an electric motor at the bike’s crank area (the part where the pedals and chainrings sit). Unlike hub motors that sit in a wheel, the mid-drive motor drives the bike through the chain and gears.

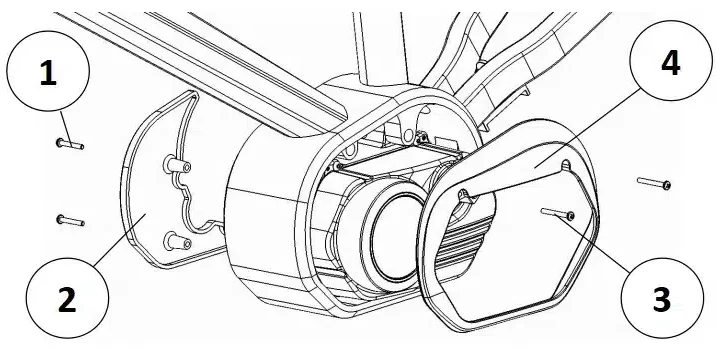

A typical e-bike conversion kit includes the motor unit, a battery (sometimes removable), a controller, throttle and/or pedal-assist sensor, wiring, and mounting hardware, all designed for smooth integration with your current bike. You fit it to a compatible bike frame and connect the battery and electronics for a seamless conversion to a new e-bike.

Mid-Drive Systems Explained

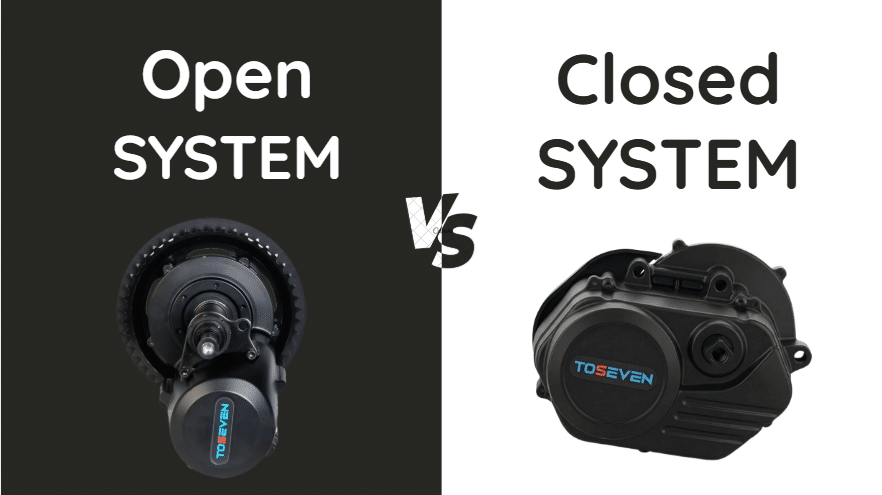

Open mid-drive systems prioritize compatibility, modularity, and user control.

Unlike OEM mid-drive motors, these are designed around global bicycle standards, allowing for the electrification of over 90% of bicycles worldwide.

The 2026 Open Mid-Drive Systems Leaders

-

To7Motor’s DM01 & DM02: Torque and cadence sensors

-

CYC Photon: Torque and cadence sensors

-

Bafang BBSHD: Cadence-only sensor

Many riders (including myself and others) prefer bikes with torque sensors because a torque sensor measures how hard you press the pedals and delivers power proportionally and smoothly, giving a natural, intuitive feel and finer control—especially during hill climbs and low-speed maneuvering.

By contrast, cadence sensors only detect pedaling speed and typically switch assistance on or off based on RPM, which can feel less responsive or abrupt. Torque systems tend to improve efficiency, handling, and overall ride comfort, though cadence systems are often simpler and less expensive. Having both is the best of both worlds.

The 2026 Closed-System Model Leaders: Bosch, Yamaha, and Shimano

While these brands represent the gold standard for refined, quiet, and integrated OEM mid-drive systems, they operate within tightly controlled ecosystems.

Key characteristics of closed systems include:

-

Proprietary motor mounts and brand-specific batteries.

-

Locked firmware and restricted component interchangeability.

-

Requirement for authorized service networks for maintenance.

What factors should I consider when choosing between an OEM mid-drive system and a mid-drive conversion?

OEM Mid-Drive System (Factory-Integrated)

Pros:

-

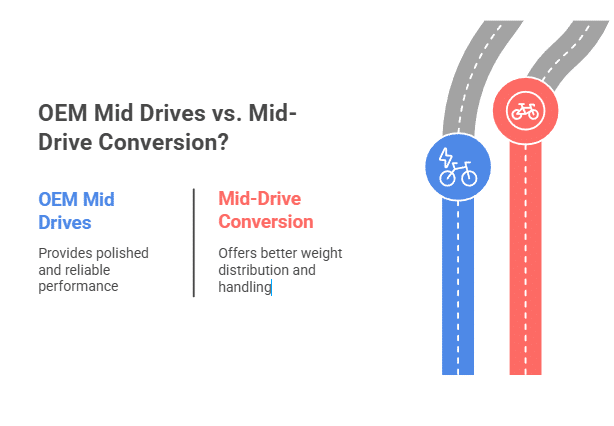

Designed as a complete system—clean integration, reliable wiring, matched components, warranty, professional setup, and often better weight distribution and aesthetics, especially when compared to a geared hub setup.

-

Ongoing dealer and manufacturer support for diagnostics, software updates, and recalls.

-

Factory-tested safety features and electronics integration (sensor tuning, motor/loss protection, thermal management).

-

Generally better fit-and-finish, fewer DIY reliability issues, and often optimized for durability under typical use scenarios.

-

Resale value can be higher for recognizable OEM models with documented service history.

Cons:

-

Higher upfront cost, fewer options for reusing your favorite existing bike, and repair or upgrade options may be limited to the maker’s parts.

-

May be heavier in some models due to integrated components and batteries that are not easily swapped or upgraded.

-

Limited customization—motor power, battery capacity, and component choices are constrained to factory configurations.

-

If the manufacturer discontinues the model or goes out of business, spare parts or specialized service can become difficult to find.

Mid-drive conversion kit (aftermarket)

Pros:

-

Lower cost than many OEM-equipped bikes, lets you keep a bike you already like, flexible on battery placement and power level, often better torque for climbing compared with comparable hub motors.

-

High degree of customization—choose motor, battery capacity, display, and drivetrain integration to suit your riding style and budget.

-

Potential for lighter overall setup if you select components carefully; ability to upgrade individual parts over time rather than replacing the whole bike.

-

Can be performed incrementally (start with motor, add larger battery later) and can preserve parts you prefer from the original bike (saddle, wheels, cockpit).

Cons:

-

Installation can be mechanical and electrical work—may require custom mounts or tools; possible compatibility issues with certain frames, bottom brackets, or gears; can void original bike warranty; wiring and looks are usually less tidy; you’re responsible for choosing quality components and setup.

-

Potential for integration problems—sensor calibration, shift sensing, or motor/chain wear can cause reliability or performance issues if not set up correctly.

-

Aftermarket support varies—software updates, diagnostics, and warranty coverage for e-bike conversion kits are often weaker than OEM systems.

-

Depending on the kit and installation, legal and insurance implications (power limits, serial number mismatch) can be more complicated than an OEM mid-drive system.

Is it better to get an OEM mid-drive system or a mid-drive conversion kit?

Choose an OEM mid-drive system if: You want a turn-key solution, consistent reliability, integrated design, and warranty coverage, and/or you don’t want to deal with installation and compatibility checks.

Choose a mid-drive conversion if you want to tackle steep hills without compromising the performance of your electric bicycle: You already own a bike you love, want better hill-climbing torque than a hub motor for a lower price, enjoy DIY projects, or want to customize power and battery placement.

What is the performance difference between mid drive conversion vs OEM mid-drive?

Hill climbing and torque:

-

Open (aftermarket) — Motor works through the bike’s drivetrain and can be tuned or paired with different chainrings and gear ratios. Result: stronger, customizable low-cadence torque for steeper hills.

-

Closed (OEM) — Motor and drivetrain are engineered together and limited by the manufacturer’s gearing and torque settings. Result: smooth, reliable hill performance within set limits, but less user tuning.

Weight distribution

-

Open (aftermarket) — Adds weight at the crank and uses an external battery. Placement depends on the kit and installation, so balancing the bike may require planning and can be less predictable.

-

Closed (OEM) — Motor and battery are integrated and positioned by the manufacturer. Result: generally predictable, well-balanced handling out of the box, with less opportunity to customize placement.

Efficiency and range:

-

Open (aftermarket) — Can be optimized by choosing gears, controllers, or sensors to favor efficiency. Result: potential for improved range when tuned for economy.

-

Closed (OEM) — Tuned by the manufacturer for a balance of responsiveness, durability, and typical use. Result: consistent, dependable efficiency and predictable range, but fewer options for aftermarket improvement.

How do OEM mid-drive systems and mid-drive conversions compare in terms of installation and maintenance?

OEM mid-drive systems vs mid-drive conversion:

OEM systems are usually easier to service through authorized shops and have cleaner wiring/mounting, while mid-drive conversions can be reliable but need more frequent checks of mounts, fasteners, chain/cassette wear (mid-drives stress drivetrains) and electrical connections.

OEM systems are simpler to hand off to dealer service; conversions often require DIY checks or an independent mechanic.

How do OEM mid-drive systems and mid-drive conversions compare in terms of cost?

Open mid-drive conversions allow component-level repairs, controller or sensor replacement, and wider third-party parts sourcing, often making them cheaper over time.

Closed OEM systems rely on the manufacturer for parts and diagnostics, which can raise costs after warranty. A small failed sensor in a closed system can force expensive motor replacements, so long-term value is typically higher for open mid-drive conversions than for closed OEM mid-drive systems.

Technical Comparison: Integrated Systems vs. Conversion Kits

This document compares factory-integrated mid-drive systems and aftermarket mid-drive conversion kits across the technical dimensions most relevant to performance, installation, durability and tuning.

It focuses on real engineering differences (mechanical interfaces, control electronics, thermal management, sensor integration, drivetrain interaction and software access) to help choose between an OEM mid-drive system and a mid-drive conversion.

Mechanical Interface and Frame Integration

-

OEM systems: OEM mid-drives are designed into the frame. Motor housings, bearings and bottom bracket shells are optimized for load paths, chainline and stiffness. Integration allows for compact packaging, lower center of gravity, and precise alignment of sprockets and gearboxes. Frames frequently use proprietary BB shells and reinforced downtubes to handle torque and shock loads.

-

Conversion kits: Typical open mid-drive kits interface with standard bottom bracket shells (commonly JIS-BSA 68–73mm, but adapters exist for other standards). They rely on aftermarket spacers, mounting plates or clamp adapters. While many modern bikes with standard BB shells can accept a conversion, alignment, chainline, and clearance must be checked. Conversions can introduce eccentric loads and require careful torque management and sometimes frame reinforcement for high-powered motors.

Bottom Bracket Standards and Fitment

Most open mid-drive conversions target BB shells in the 68–73mm JIS-BSA range. That enables wide compatibility (often 90% of bikes) with common road and mountain frames.

However, OEM systems often use custom BB geometries and integrated bearings that are not compatible with a generic conversion motor without frame modification or proprietary adapters.

Powertrain Architecture and Drivetrain Interaction

-

OEM systems: OEM designs often integrate the motor and gearing with the bike’s drivetrain via optimized reduction gear ratios and bespoke chainring sizes. They coordinate with the bike’s gearing to balance torque delivery and chain wear, especially when using a geared hub motor. Many OEMs use multi-stage planetary gearboxes inside the motor housing to achieve high torque with compact size.

-

Conversion kits: Aftermarket mid-drives typically put the motor’s torque through the existing bicycle drivetrain and derailleur system. Conversion motors are available in a range of reduction ratios; selecting the correct ratio is essential to avoid excessive drivetrain wear or insufficient low-end torque. Conversions can stress chains, cassettes and derailleur hangers if motor torque exceeds component ratings.

Sensor Suite and Control Systems

-

OEM systems: OEMs commonly ship torque sensors (integrated into the cranks or spindle) and high-fidelity cadence sensors, connected over CAN or proprietary bus systems to a tightly integrated motor controller. This yields smooth, predictable pedal-assist curves, faster response, and lower latency between rider input and motor output, making it ideal for tackling steep hills on an e-bike conversion kit. OEM ECUs often integrate with bicycle displays and bike-specific modes (walk, eco, trail), enhancing the experience of riding an electric bicycle.

-

Conversion kits: Many conversion kits use cadence-based or basic torque sensors with simpler controllers. High-end kits may offer programmable torque sensors and CAN bus compatibility, but lower-cost kits often provide less refined pedal assist behavior (stepped assist levels, slower response). Aftermarket controllers can be programmable, but integration with bike-specific displays and switchgear may require extra wiring or custom firmware.

Firmware, Diagnostics and Customization

| Aspect | OEM Mid-drive System | Mid-drive Conversion Kit |

| Firmware access | Typically locked or restricted; updates issued via dealer or app with signed firmware. | Often fully accessible or user-programmable; many controllers accept third‑party tuning tools and open protocols. |

| Customization | Limited to OEM-supported modes and parameters; constrained to meet warranty and legal limits. | Extensive—torque curves, speed limiters, assist levels, thermal profiles can be modified. |

| Diagnostics | Integrated diagnostics, error codes tied to OEM service tools and CAN telemetry. | Controller-specific diagnostics may lack unified vehicle diagnostics unless aftermarket tools are used. |

Weight Distribution, Aesthetics and Packaging

-

OEM systems: Designed to minimize silhouette and distribute mass near the downtube or bottom bracket. Integrated batteries and internal cable routing improve handling and weather protection. Aesthetics are clean and aerodynamic.

-

Conversion kits: Often heavier as standalone units plus an externally mounted battery or rack battery. Installation can shift weight higher or rearward (if using a rack battery) and lead to different handling characteristics. Exposed wiring and mounts are less integrated.

Summary Table

| Category | OEM Mid-drive System | Mid-drive Conversion |

| Integration | High (frame, battery, wiring) | Medium (adapter-based) |

| Firmware access | Locked/controlled settings on the controller help manage power output. | Open/programmable |

| Thermal design | Engineered with frame | Kit-dependent |

| Drivetrain impact | Optimized | Can increase wear if mismatched |

| Installation complexity | Low (delivered assembled) | Medium–High (mechanical & electrical integration) |

| Cost | Higher upfront | Lower to moderate, scalable |

| Warranty & compliance | OEM-backed & certified | Vendor-dependent; may affect bike warranty |

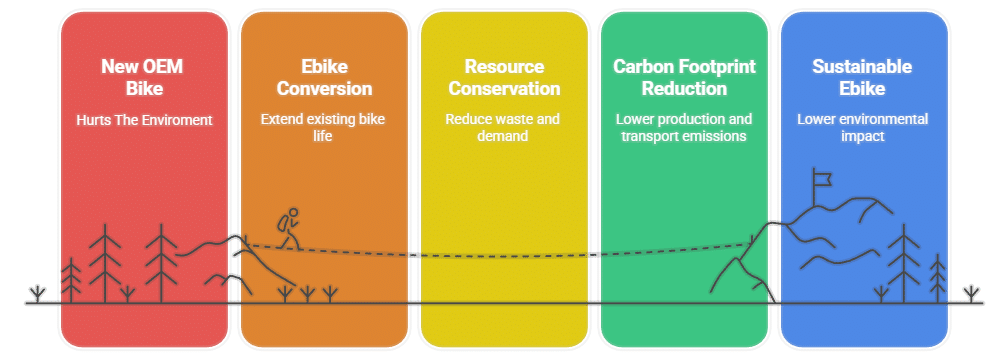

What are the potential environmental benefits of ebike conversion versus buying a new OEM-equipped bike?

Lower embodied carbon:

Manufacturing a new e-bike requires mining, processing metals and composites, producing a motor and battery, and shipping the finished bike.

Converting reuses the original frame and many components, avoiding much of that manufacturing energy and the associated CO2 emissions.

Reduced material demand:

Conversion kits such as To7’s minimizes the need for new raw materials (aluminum, steel, carbon, plastics, electronics), easing pressure on mining and material-processing supply chains.

Buying a new OEM-equipped bike introduces additional packaging, accessories, and often duplicate parts (lights, racks, fenders). A conversion kit typically generates less packaging and fewer redundant parts, and reuses existing bike components.

Extended E-bike lifespan:

Converting a functional bicycle postpones disposal and replacement, which reduces lifetime waste and spreads the environmental cost of the original build over more years of use.

Lower transport emissions:

Buying locally-sourced conversion kits or installing locally reduces long-distance shipping of finished e-bikes imported from overseas, cutting transportation-related emissions.

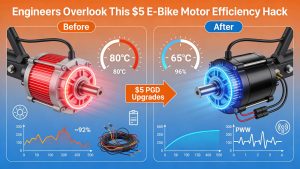

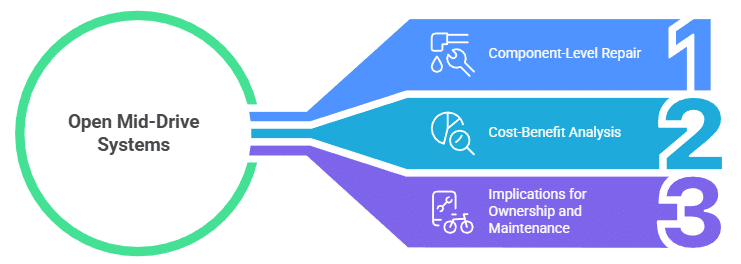

The Right to Repair: Why a $5 Sensor Shouldn’t Cost You a $1,000 Mid Drive Motor

Component-Level Repair: Pros and Cons

Component-level repair is a significant advantage of open mid-drive systems. Pros include lower maintenance costs and increased longevity of the ebike. Cons may involve the need for specialized knowledge and tools for DIY conversion.

However, the ability to replace a faulty sensor or controller without replacing the entire motor is invaluable. This contrasts sharply with proprietary systems, where a minor issue can lead to a costly full unit replacement.

Cost-Benefit Analysis of Modularity

The modular design of open mid-drive systems offers substantial cost benefits. When a component fails, only that specific part needs to be replaced, reducing expenses. While the upfront cost of a mid-drive conversion kit might be higher, the long-term savings from modularity and repairability outweigh this initial investment.

Users benefit from the freedom to upgrade components individually, especially when using conversion kits typically designed for new bikes. The modularity of open systems allows users to tailor their ebike to their individual needs.

Implications for Ownership and Maintenance

The right to repair significantly impacts ebike ownership and maintenance, encouraging users to explore mid drive bikes and hub drive alternatives.

With open mid-drive systems, owners have the freedom to perform maintenance, source replacement parts, and upgrade components. This level of control extends the life of the ebike and reduces long-term costs.

Conversely, proprietary systems restrict user intervention, leading to dependence on authorized service centers and potentially higher maintenance expenses. Understanding these implications is essential for making an informed decision.

What are the disadvantages of mid-drive ebikes?

-

Maintenance headaches: More wear on chain, cassette and chainrings—frequent replacement and tune-ups needed.

-

Higher cost and complexity: Typically pricier, heavier electronics, and harder/expensive repairs than hub-motors, though conversion options while still having this issue, are cheaper when it comes to this.

Frequently Asked Questions About E-Bikes

Can I install this myself?

If you can change a tire and have a basic toolset, yes. It’s a 2-hour project for most DIYers. Installing an electric bike conversion kit, especially a mid drive motor kit, is generally straightforward.

These e-bike conversion kits are designed to be user-friendly, with comprehensive instructions and readily available online resources, including bike forums for additional support.

Will it ruin my bike frame?

No. Mid-drives distribute weight centrally, which is actually better for your frame’s geometry than hub motors.

A mid-drive motor, such as To7motor’s DM01, is mounted near the bottom bracket (BB), distributing weight evenly. By choosing a mid drive conversion, you can enhance, rather than compromise, the structural integrity and handling of your current bike frame.

Is it legal?

To stay within EN15194 standards in Europe (EU), stick to 250W continuous and 25km/h limits. In the USA, you have more freedom (up to 750W/Class 3), but high-quality Hydraulic Disc Brakes are recommended to handle the added torque.

Be sure to check your local laws regarding maximum motor power and speed limits for ebikes.