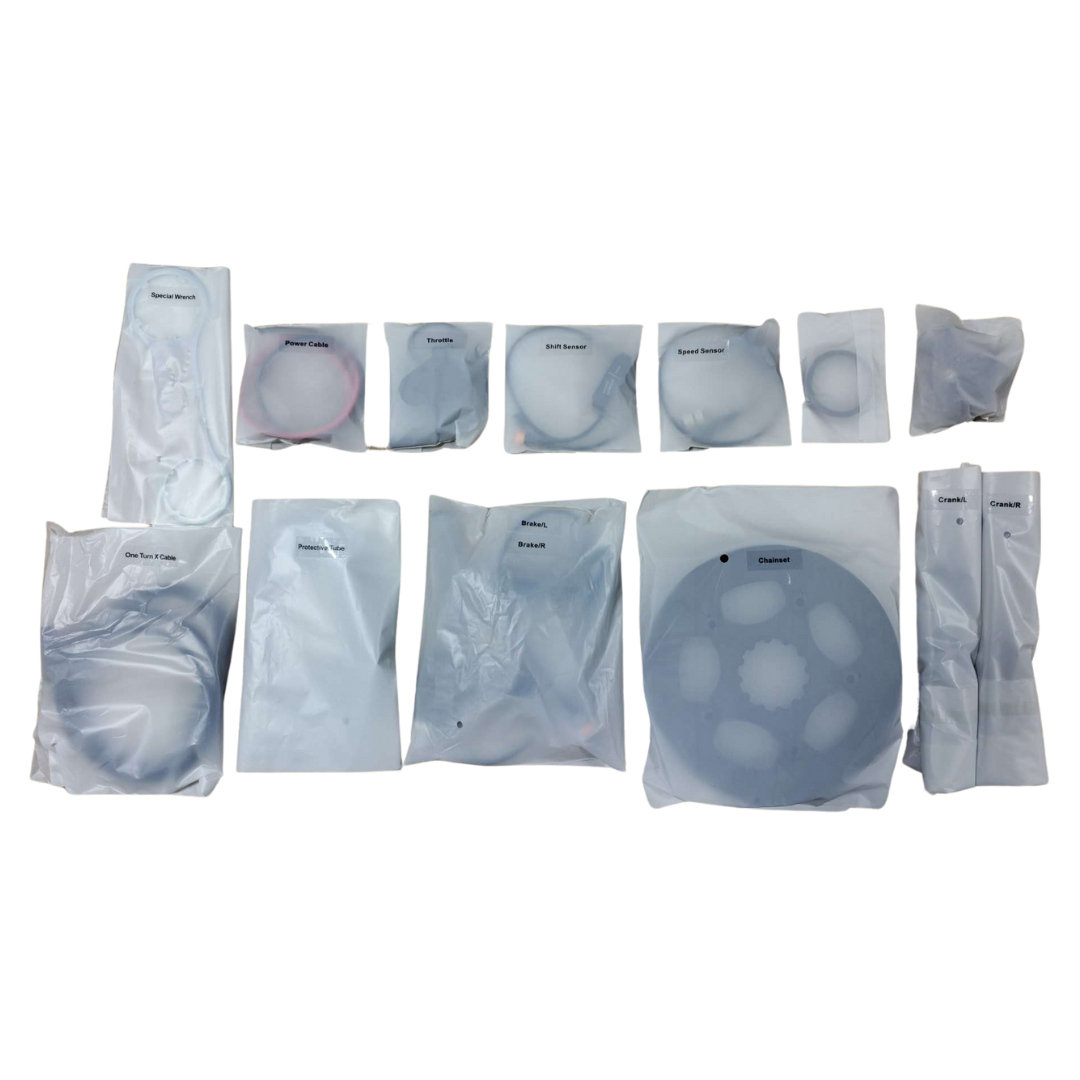

STARTING FROM APRIl 1ST 2024: To7Motor Switches to Biodegradable Bags for a Greener PLANET

Starting April 1st, To7Motor is taking a significant step towards a more sustainable future by switching to biodegradable bags for all of our product packaging. As a company committed to reducing our environmental impact, we are excited to announce this eco-friendly change that will help minimize waste and protect our planet.

Our new biodegradable bags are made from plant-based materials such as cornstarch and cassava, which break down naturally without leaving harmful residues behind. Unlike traditional plastic bags that can take hundreds of years to decompose, our biodegradable packaging will completely degrade in a matter of months when exposed to the right conditions, such as in a compost pile or landfill.

By choosing biodegradable bags, we are not only reducing the amount of plastic waste that ends up in landfills and oceans, but we are also minimizing our carbon footprint. The production of these eco-friendly bags emits fewer greenhouse gases compared to the manufacturing of conventional plastic bags, further contributing to our sustainability efforts.

At To7Motor, we understand the importance of taking responsibility for our environmental impact, and switching to biodegradable packaging is just one of the many steps we are taking to create a greener future. Join us in our mission to promote sustainability and protect our planet, one biodegradable bag at a time!

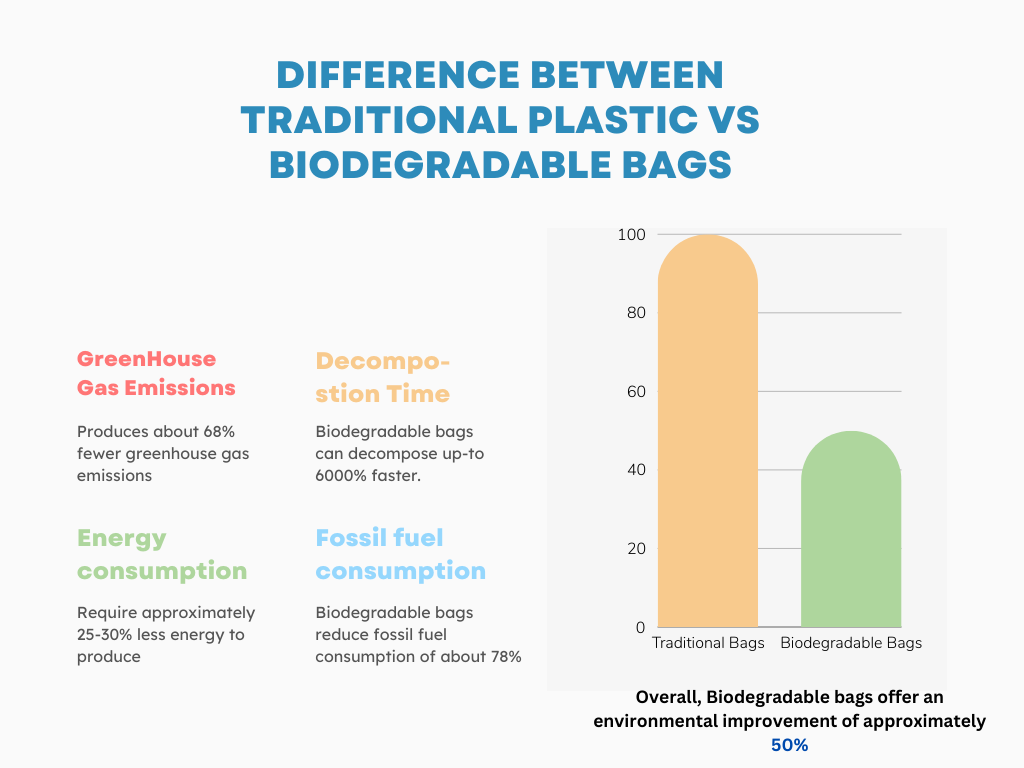

BUT, LET’S REALLY LOOK AT THE BENEFITS OF SWITCHING TO BIODEGRADABLE BAGS:

I mean, just look at the improvements, the differences, the benefits between biodegradable bags and traditional bags, it’s incredible, below we go more in-depth with the explanations

Greenhouse Gas Emissions (kg CO2 equivalent per 1000 bags):

- Traditional Plastic Bags: 52.09 to 150.36

- Biodegradable Bags: 21.06 to 56.86

- This represents a 13.53% to 62.19% reduction in emissions by switching to biodegradable bags.

Decomposition Time:

- Traditional Plastic Bags: 100-500 years

- Biodegradable Bags: 3-6 months (in commercial composting conditions)

- Biodegradable bags break down much faster, reducing long-term waste.

Energy Consumption in Production (MJ/kg):

- Traditional Plastic Bags: 80.0 to 90.0

- Biodegradable PLA Bags: 57.0 to 66.0

- Producing biodegradable PLA bags uses about 25-30% less energy compared to traditional plastic.

Fossil Fuel Consumption (kg oil eq/1000 bags):

- Traditional Plastic Bags: 2.0 to 2.5

- Biodegradable Bags: 0.2 to 0.8

- Biodegradable bags require significantly less fossil fuels, as they are made from renewable plant-based materials rather than petroleum.

APART OF GROUPS FIGHTING FOR CLIMATE CHANGE!

Now, with our switch to biodegradable packaging made from eco-friendly materials like PLA and PBAT, we are taking our environmental responsibility a step further. By significantly reducing the fossil fuel consumption and carbon footprint associated with our packaging, we are demonstrating our dedication to minimizing waste and protecting the planet at every stage of our products’ life cycle.

Through these initiatives, we are proud to consider ourselves part of a growing global community of businesses, organizations, and individuals who are actively working to combat climate change. We believe that every action counts, and by making sustainable choices in our operations and products, we can inspire others to do the same.

WHAT’S OUR END-GOAL?